Increased laser power and assist gases will open up new markets.

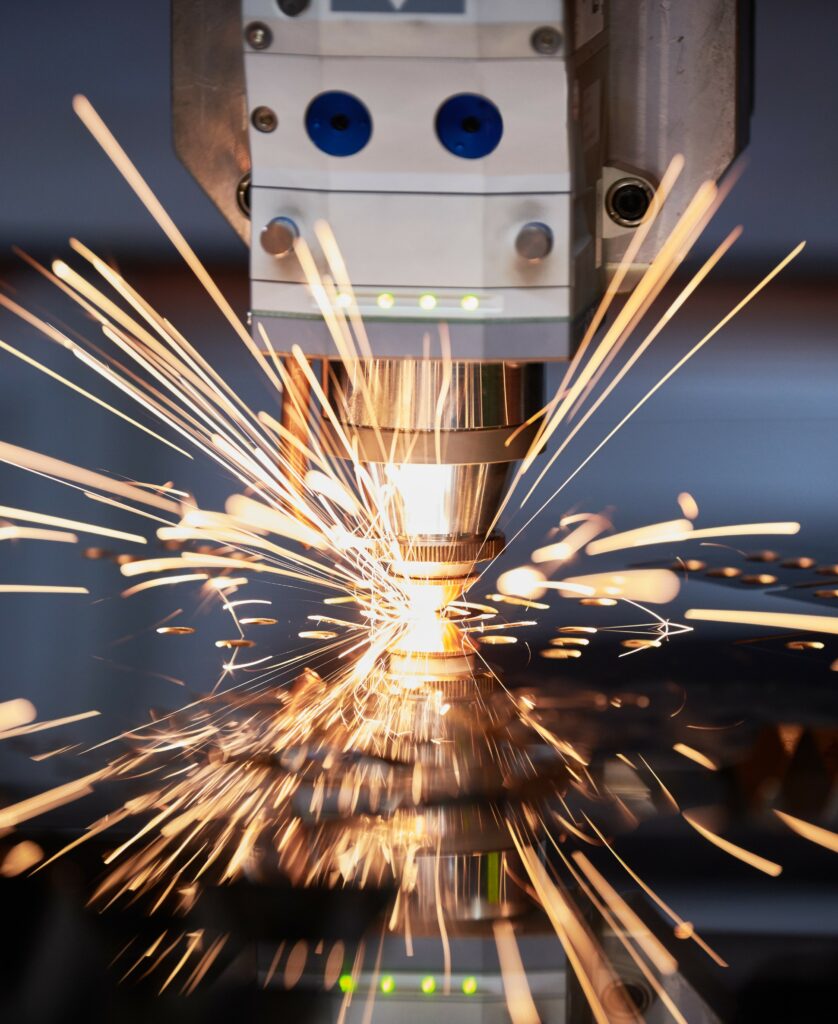

Messer Cutting Systems, Inc. (Menomonee Falls, WI) – With the advent of increasing laser power sources, the future is very “bright” for the metal fabrication world. The direct correlation between increased power and the laser cutting process in thick mild steel plate is the end user is going to be able to change from using oxygen assist gas to gases such as nitrogen, air, and mixed gases to process thick plate (mild steel). This will open up new markets that are currently being satisfied by plasma and flame cutting.

This will be a game changer as the edge quality and cutting speeds will drastically increase and eliminate the additional process of removing the oxidation layer that is created when using oxygen-assist gas. In thick plate if this layer is not removed paint will not adhere to the cut edge.

As this industry has learned through the years, the cutting head is one of the most important components of the laser cutting system. We all know the painstaking evolution process of ensuring zero contamination in the cutting head cavity. The great news is that we have cutting heads that will handle up to a 50 kW power source.

This technology married with stable laser power sources will provide stable cutting processes in thick plates.

As power increases there will be significant gains in cutting speeds and acceleration in thinner sheets. In this case, height sensing units are becoming more and more responsive allowing cut speeds up to 3,500 inches per minute, in some cases.

The cutting process can be so fast that without some type of automation applied to the loading and unloading of the raw material, the operator is unable to keep pace with the machine. Innovative part sorting has also become a factor in eliminating the issue of operator intervention and pauses in production due to the operator’s ability to keep pace with lightning fast cutting speeds.

The laser cutting world is evolving rapidly and the future is “bright”! — Adam Bryan, laser project manager, Messer Cutting Systems

Article: 2023, Nov. -Dec. Fabricating & Metalworking