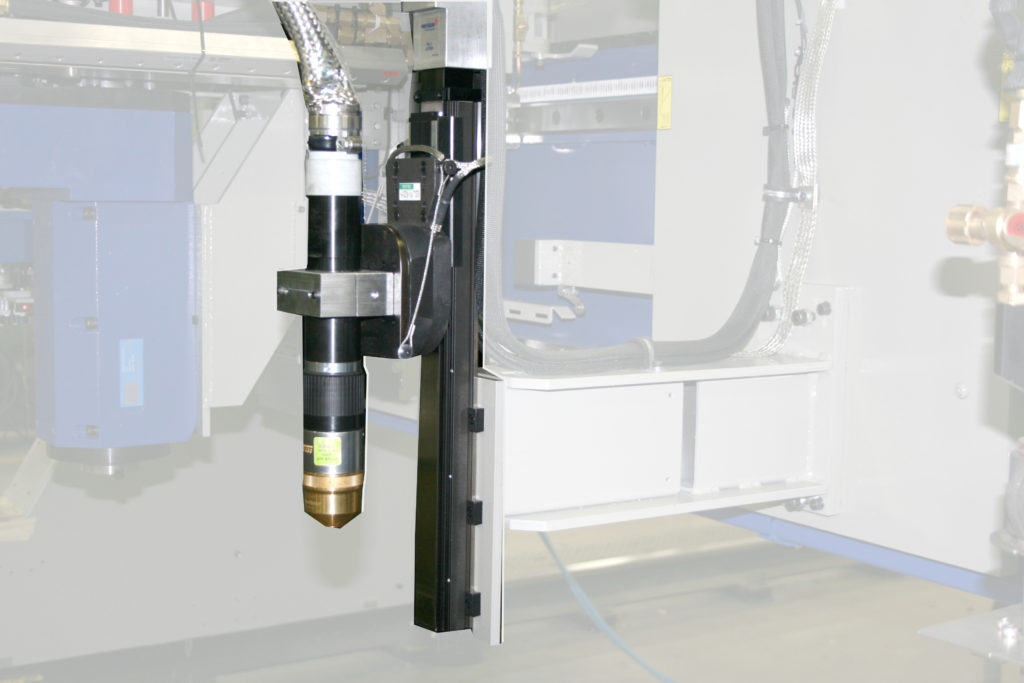

The PL-1 Plasma Torch Lifter combines plasma arc voltage monitoring with

a CNC closed loop positioning axis to greatly enhance plasma height control in

plasma cutting, resulting in a higher duty cycle and better cut quality.

Coupled with the SureStop Collision Sensor if a collision occurs while cutting the magnet that holes the torch rigidly in place breaks free, and the process shuts off. The torch is protected from damage due to programming, obstructions on the cutting table and improper material positioning. Resetting after a collision takes only a few seconds.

The PL-1 torch lifter with height control is done through the CNC

software, resulting in less hardware and more reliability. The system is

flexible and allows the user to: program pierce height, retract distance, IHS

slowdown height, and conditional height freeze. Set initial height sensing via

ohmic position detection. Set the arc voltage range (50-300 volts DC). Make servo loop adjustments for position and

velocity gain. Set semi or full automatic operation.

The PL-1 uses a 200W AC digital brushless servo motor and twin steel

guide ways with a precision ball screw to provide travel lengths of

4″-8″, depending on machine application. Moving elements are sealed

with protective steel strips and combine for tracking accuracy of +/- 0.3 arc

volts.

- Ultrafast positioning of 880 IPM with .75g acceleration, increases productivity by minimizing no-productive time.

- Torch lifters utilizing Messer Optimized System Technology (MOST), can reduce cycle times by as much as 30% over previous designs.

- Optimal positioning of the plasma, torch produces quality parts that require little to no secondary operations.

- Non-productive time is greatly reduced due to an adaptive IHS system that “learns” the height of the plate on the cutting table.

- Includes our proven arc voltage sampling system to compensate for plasma electrode wear while producing accurate, repeatable parts.

- Process optimization feature minimizes up/down time of the torch(es) between pierces.

- Automatic consumable wear detection reduces operating costs while freeing the operator to perform other duties.

- SureStop Collision Sensor is quick, simple and easy to realign for torch protection.

Contact

Messer Cutting Systems, Inc.