WHAT IS A SLAT?

Slats are thin mild steel plates that are horizontally spaced apart on a cutting table. The plate rests on these slats. We will present different slat tray options which allow businesses to improve their cut quality based on the material and process they choose. Let’s answer some common questions about slats and slat trays while taking a look at slat types and options such as drill tray comb plates, comb plate risers, and serrated slat frames.

What is a slat tray for drilling?

A slat tray assembly is a fabricated structure that holds the slats and allows them to be replaced quickly in modules rather than individually. Drawings are available for users to make replacements. Optional designs include standard slats for drilling applications.

BURN TABLE SLATS FOR DRILLING

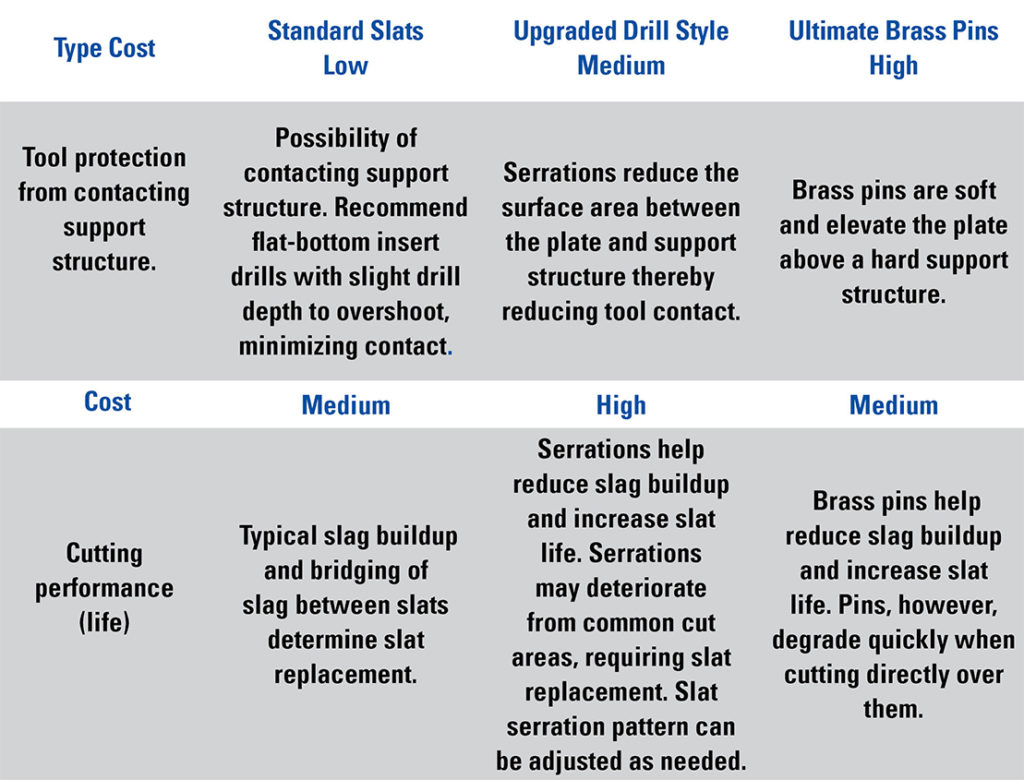

Slat Options

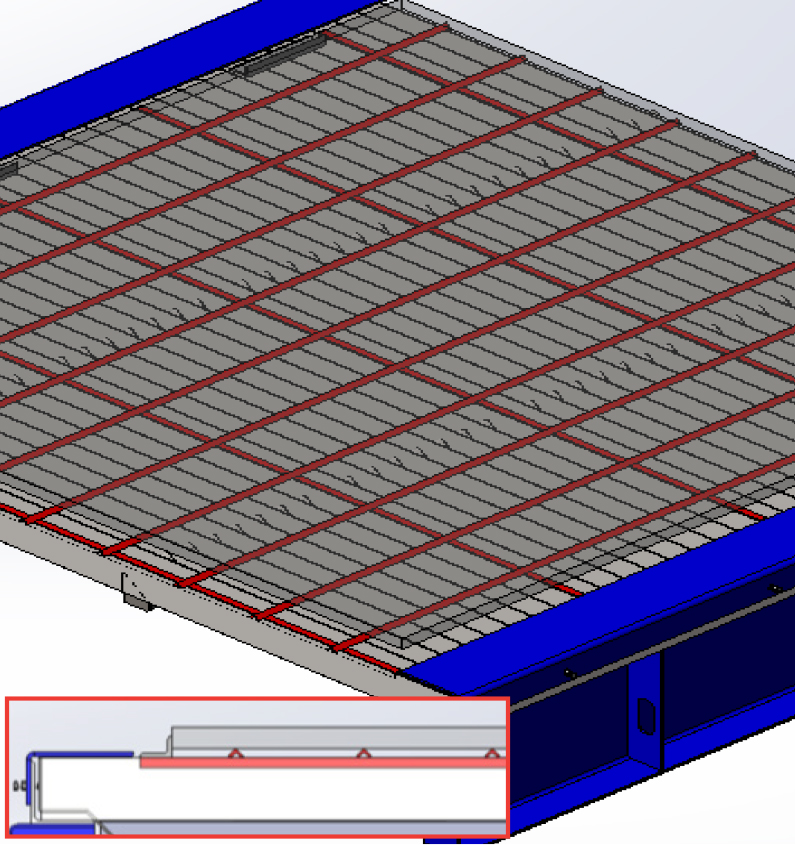

Drill Tray Plate Style

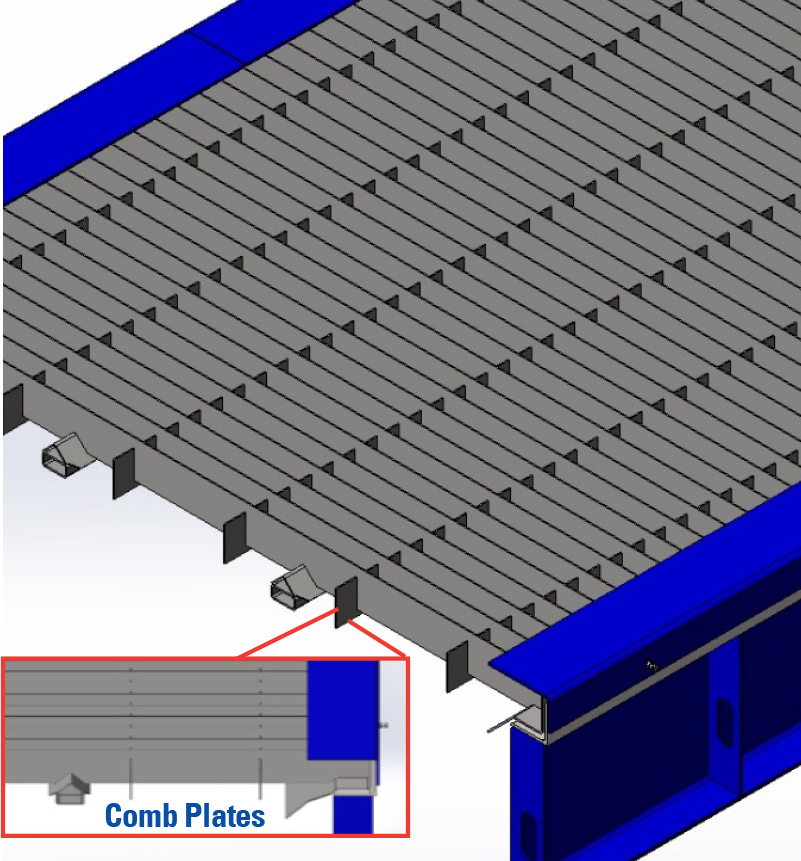

Features:

- Replaceable slat trays.

- Standard sheared cutting slats.

- 3½-inch slat-to-slat spacing.

Options:

- Longitudinal “Comb Plates” minimize longitudinal plate movement.

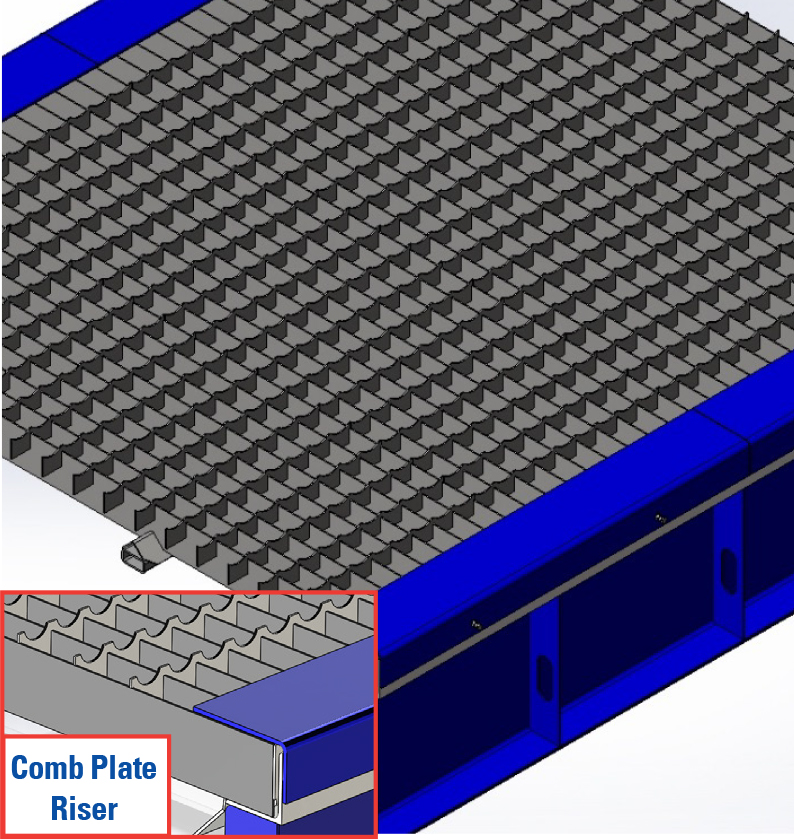

Comb Plate Riser

Optional:

- Longitudinal “Comb Plate Risers”.

- Minimize longitudinal plate movement.

- Reduce surface area for drills to contact slat supports.

- Minimal increase to the plate support surface.

Customer Provided Angle Supports

Features:

- The operator can add welded 1″ x 1x¼-inch-thick angle iron grid on top of the table to offset the plate ¾ inches from support slats.

- Angle iron can lay between the slats for less height.

- The welded grid can be added or removed from the table.

- The plate should be tack-welded to the grid or sacrificial angle.

- Note: Grid adds ¾ inches to table height. Check thick plate for machine clearances.

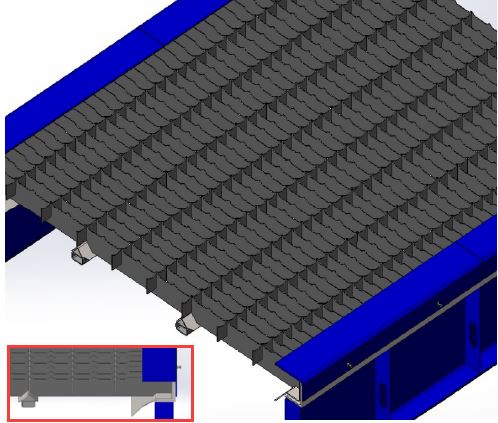

Serrated Slat Tray

Features:

- Replaceable slat frames.

- Scalloped plate support tray reduces tool to support contact.

- Alternating slat serration location every other slat.

- Serration size, profile, and location can be customized when replacing slats, depending on the cut part type and size.

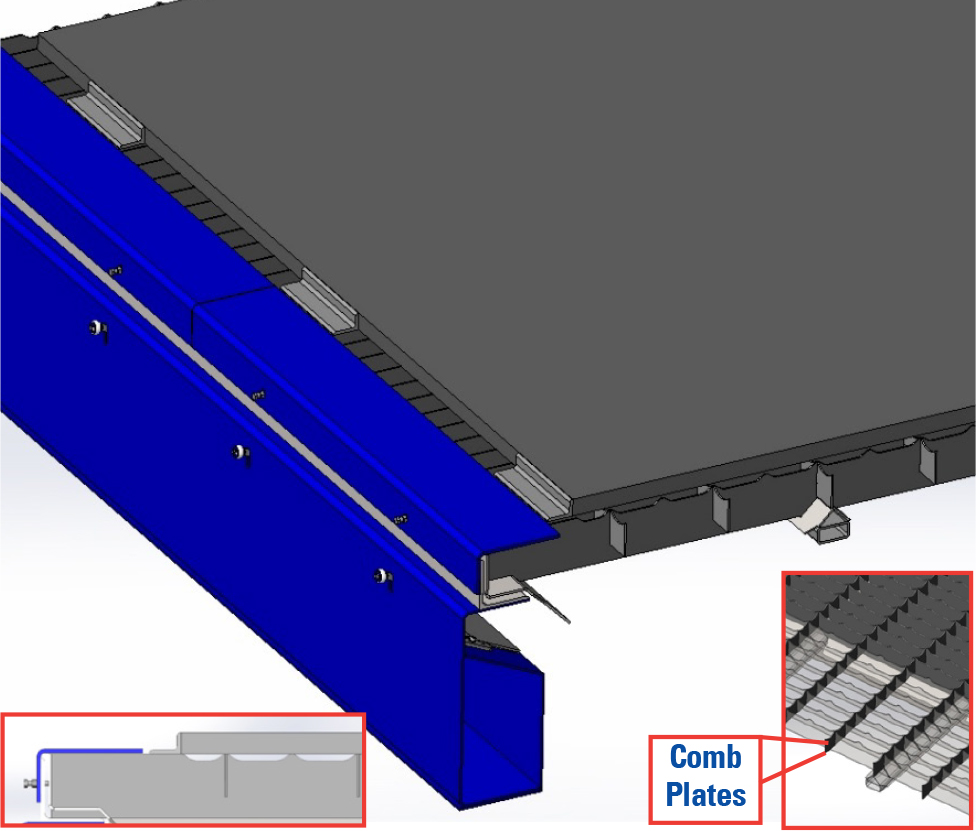

Serrated Slat Tray

Features:

- Sacrificial angle iron to be tack-welded to slat frame and plate, lessening plate vibration for higher cutting speeds.

- Slat trays are pinched horizontally to eliminate side-to-side movement.

- Longitudinal “Comb Plates” minimize longitudinal plate movement.

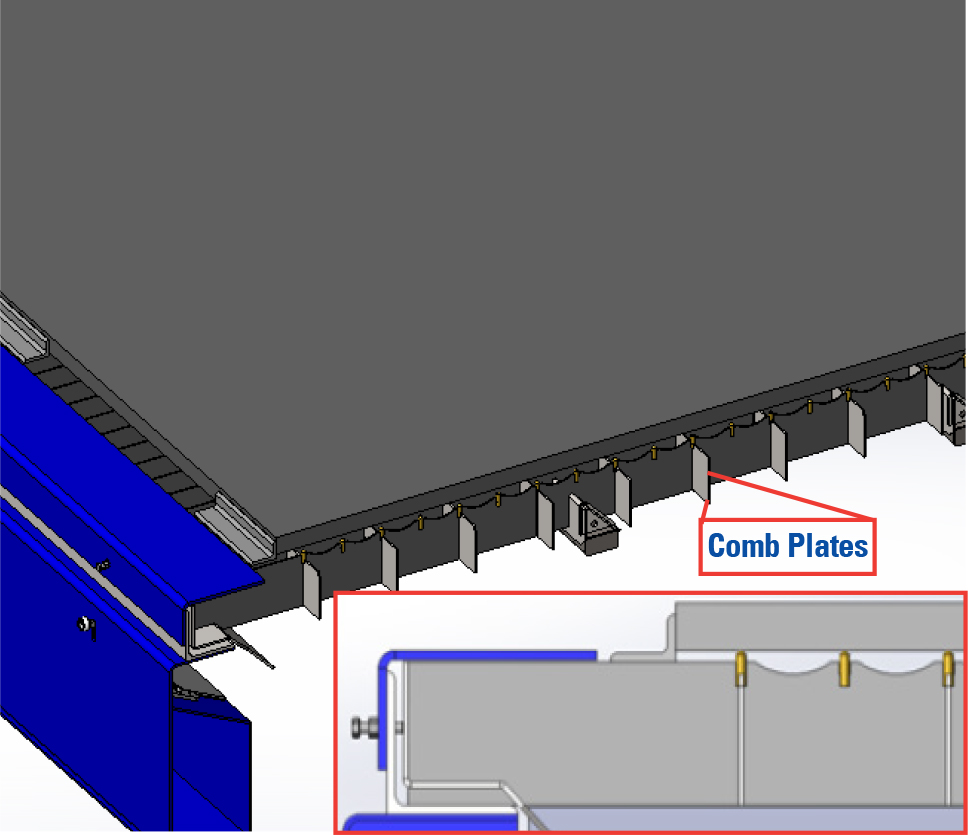

Serrated Slat Tray with Brass Pins

Features:

- Sacrificial angle iron to be tack-welded to slat tray and plate, lessening plate vibration for higher cutting speeds.

- Slat trays are pinched horizontally to eliminate side-to-side movement.

- Longitudinal “Comb Plates” minimize longitudinal plate movement.

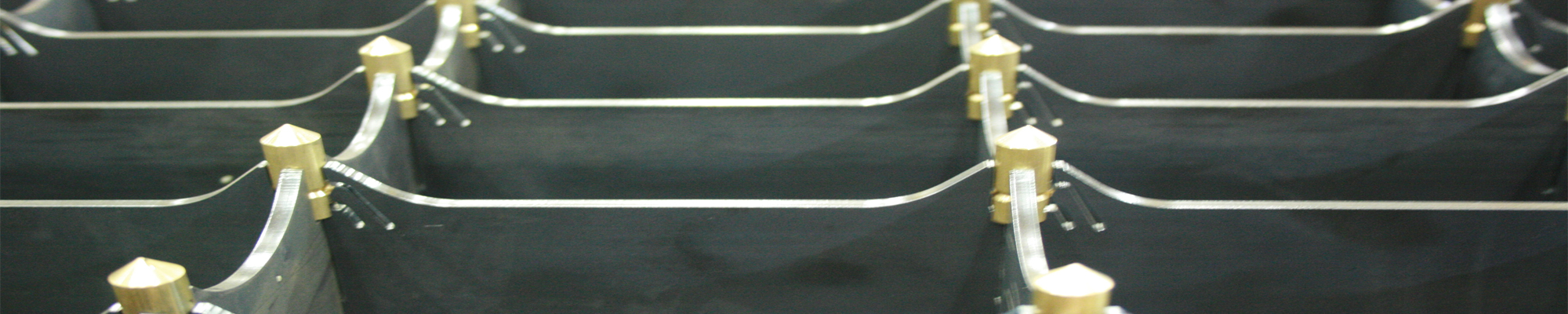

Pin Groove Style Trays with Brass Pins

Features:

- Replaceable slat frames.

- Scalloped plate support tray reduces the risk of cutting tool hitting the slat.

- The plate contact surface is made from machined brass to extend tooling life.

- Optimized for drilling.

Contact

Messer Cutting Systems, Inc.