Anchorage firm buys cutting-edge computer-controlled steel processor

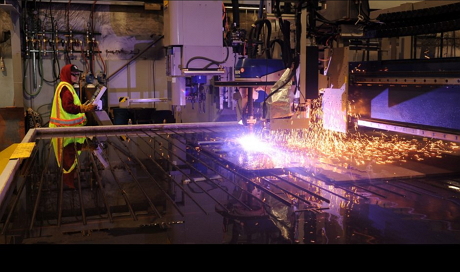

Ancorage, Alaska, USA. – Anchorage steel processor Steelfab has just finished assembling a new computer-controlled steel processing machine, the only one of its kind in the state.

The Messer MPC2000 can cut steel plate up to three inches thick and can handle pieces up to 17 feet wide and 55 feet long. It is capable of doing work that before had to be done in the Lower 48.

Steelfab execs said it will make a big difference in the time and cost of making complex steel, stainless steel and aluminum and parts.

Steelfab is the state’s largest steel service center and processor, offering 100,000 tons of product annually. Its main clients are in the oil and gas, mining and heavy construction industries. It sells and modifies steel plate and can make pressure tanks. For many of the company’s clients, custom or modified steel parts require a long and complex crafting process.

A computer design specialist creates a template for the machine, and a lone worker operates it. The parts it makes are used in bridges, buildings, girders, I-beams and pressure tanks. Steelfab said that the machine works with an accuracy of just 1/10,000th of an inch — about 40 times smaller than the thickness of the average human hair.

The MPC2000 can cut with a high temperature plasma torch. It can drill. It can bevel the steel’s edge (a process used for welding plates together.) It can also tap — or thread the holes it drills. And it can do it all at the push of a button. Steelfab said it replaces eight separate processes, reducing the time it takes to make a steel part from three hours to just several minutes.

“Before, you would cut the plate, then you would go lay the holes out and then somebody would drill the holes,” said Steelfab president C. Richard Faulkner. “Then somebody would go over and bevel the edges on the plate. They were all completely different and separate processes and now this machine does all of it.”

The machine even has its own printer — permanently marking each custom part with its own tracking number. Faulkner said the Messer MPC2000 cost is “in the high six figures.”

While not technically a manufacturing machine — the steel comes to Alaska in large plates — Steelfab believes the machine will pay off for the company, even though Faulkner admits it was purchased at an inconvenient time, especially since Steelfab does a lot of business with Alaska’s oil producers.

“We ordered it just before the oil prices went down,” Faulkner said. “But our steel service center helps keep the machines busy.”

Published on Alaska Dispatch News

https://www.adn.com/article/20150910/anchorage-firm-buys-cutting-edge-computer-controlled-steel-processor