Your Competitive Advantage

Leap in performance in laser technology!

Whether it is rapidly increasing laser power with even different fiber types or even new cutting gases: Today’s laser machines must be able to follow current trends with new innovation, applications are more effective and transparent. In addition, the increasing shortage of skilled workers it creates a need for manufacturing plants to become more self-sufficient. One machine operator alone has ability to supervise several machines.

Automation throughout the entire production cycle was at forefront of the ELEMENT L’s development.

Specifications & Capabilities

Designed for strength, durability, and precision, the ELEMENT 400L Unitized machine will give you a competitive edge with customizable configurations and premier features. Regardless of whether you choose plasma, laser, both plasma and laser bevel cutting, your ELEMENT 400L Unitized system will have the following specifications and capabilities.

- 6, 8, or 10 feet of cutting width.

- 10 to 54 feet of cutting length plus park space for the machine.

- Laser beveling up to 50°.

- Precisely machined way and gear rack mounting surfaces.

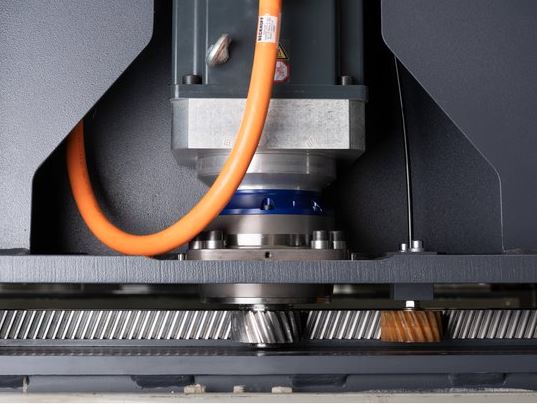

- Linear ways coupled with helical gears.

- Laser and plasma beveling.

Contact

Messer Cutting Systems, Inc.

Download

Increased Productivity

Improved User Experience

The new, easy-to-use Global Connect CNC control equipped with 18.5” touchscreen helps to save paper and provides a clear overview of all production data in digital form.

Increased Safety

With modern fiber laser technology, a full enclosure that is light-tight.

For safety, its access points for material and people are monitored.

Precitec ProCutter 2 Laser Cutting Head

This laser cutting head auto focuses its position for maximum efficiency, performing constant, high-cutting speeds at any operating temperature. The laser beam is completely sealed against micro-dust, maximum laser power up to 20kW, and a focal length of either 150mm or 200mm with a zoom head.

Improved Cutting Quality

Selected premium components and smooth, vibration-free tool path movements thanks to helical rack and pinion drive systems.

Compact and User Friendly

The Element 400 L Unitized is the complete cutting package, featuring a compact cutting machine and downdraft exhaust table operated by a PC-based modern touch screen CNC control. With a smaller footprint than similar machines, the Element 400L Unitized helps you save space without compromising your capacity for productivity. This machine is just as powerful and functional as larger models and can help you make the most of your floor plan.

Efficient

This US-manufactured cutting machine boasts acceleration and speeds that can support multiple laser or plasma heads with no loss of performance across all applications. With plasma bevelling in particular, the Element 400L Unitized has already scored well for excellent dynamic behavior.

Interconnected

Designed for the future, this machine features bluetooth connectivity, IoT compatibility, and more so you can access, analyze, and share important data on a desktop, ipad or mobile phone via OmniFab Software. Add additional material handling solutions for additional plate processing solutions.

Laser Z-Axis Slide – GL200

The precision ball screw and double guide rollers provide a smooth and rigid platform for vertical positioning of the cutting or marking tool, including sealed bearings that are virtually maintenance-free, increasing accuracy and productivity at the same time.

With the Laser Z-Axis Slide, you’ll have access to:

- Stroke speed of 1,182 ipm/ min at 0.6G.

- Maximum stroke length of 11 inches.

- Maximum weight load of approximately 220 pounds.

Laser Station Outlet Equipment

The station outlet consists of pre-assembled piping with regulators for selected laser gases. The appropriate fittings are attached to the outlet side to mate with the Messer Cutting Systems supplied hoses, with the station outlet designed for mounting in close proximity to the X-axis powertrack entry point.

Plasma

For plasma cutting operations, the Element 400 L Unitized supports the following plasma systems:

- Hypertherm HPR400XD HyPerformance Plasma System – Automatic Gas Console.

- Hypertherm XPR family.

Messer Cutting Systems GL200 Plasma Torch Height Control

For optimal plasma cutting torch control, we’ve equipped the Element 400 L Unitizes with the GL200 Plasma Torch Height Control, offering the following features:

- Slide speed of 1180 ipm.

- Highly repeatable motion: .01 mm (0.00039”).

- 200 mm (7.87 inch) Z-axis stroke.

- Rigid steel structure.

- Twin steel guide ways with precision ball screw.

- Multiple, variable retract positions.

- Auto Kerf crossing detection.

- 400W, brushless AC drive system with EtherCAT interface.

- Motor-mounted encoder.

Global Connect Control & OmniFab Software Suite

Messer Cutting Systems is dedicated to advanced digital optimization, so we have outfitted the Element 400L Unitized with Global Connect Control and the OmniFab software suite, offering digital solutions for material handling and data interconnectivity. The use of these technologies allows for the improvement of productivity throughout the entire workflow of the thermal cutting process; integrating Messer engineering technology into your workflow from the office to the factory floor, the OmniFab software suite is a tailor-made solution for improving the efficiency of order-related production.

SureStop Collision Sensor

The Messer Cutting Systems SureStop magnetic protection system holds the cutting head rigidly in place while cutting. When a collision occurs, the machine stops, shutting off the process and protecting the cutting head from related damage due to programming errors, obstructions on the cutting table, and improper material positioning. Used in conjunction with the CSL Lifter, this system is not intended as a replacement for proper programming techniques for collision avoidance but adds an additional layer of protection.

The Slagger® Slag and Smoke Removal Cutting Table

The Slagger® self-cleaning zoned and ducted exhaust table helps reduce downtime for maximized productivity. It will support pallets with up to 2-inch plates over its entire surface. The operator control station for the Slagger® is located at the front of the machine.

With a cutting surface of 6’, 8’, or 10’ wide by 10’-54’ long, the Slagger® table supports up to 2-inch thick plate over its entire surface, or smaller sizes of thicker plate and features one exhaust duct module for reduced downtime and improved operator safety.

Along with the Slagger® table, you’ll get:

- Slagger® Blade Assembly.

- Wireless Remote Control for Slagger® Table.

Shuttle Table

The shuttle table horizontal pallet transfer mechanism utilizes a heavy-duty rack pinion system with VFD controlled motor, providing a reliable means of transporting pallet trays at 1,000 IPM between the load and cut location with continuous monitoring from Global Connect.

Plate loading and unloading is ergonomically friendly with an exchange time of under three minutes, and this action can be performed from three directions, providing flexibility for material flow and location.

Optional Features

In addition to the standard features on the Element 400L Unitized, you can also choose from additional options, including:

Traveling Light Curtain

These light curtains are positioned to offer safety protection at the front and rear of the machine, automatically stopping the machine when an obstruction passes through the viewing field.

Shuttle Enclosure

This Class 1 laser enclosure surrounds the cutting portion of the machine, offering enhanced safety and protection during operation and reducing operator exposure to arc glare, noise, and smoke. The electric rollup door has safety interlocks that protect the shuttle and cutting sequence, as well as full access to the machine when necessary. The shuttle enclosure also includes six machine viewing cameras that are mounted inside the enclosure.

Gain Access to Our Professional Repair Service

With any purchase of the new Element 400L Unitized or the Element 400 Unitized machines, you will gain a one-year subscription to the following repair and diagnostic services.

Virtual Service

Our Virtual Service allows our team of experts to remotely diagnose many problems that, in the past, would have required an on-site technician. Through the use of your internet connection, we are able to view the same data being displayed to the operator back at our facility. Now through the vast amount of diagnostic information in the Global Connect, including an on-board oscilloscope, we can perform remote troubleshooting and updates to your software as necessary.

Each subsequent annual subscription rate is $600, provided you are part of our Preventative Maintenance Program. Otherwise, the subsequent year subscription rate is $1,200.

Visual Service

Visual Service adds a sense of sight for enhanced virtual assistance. In addition to using the Global Connect as a portal for troubleshooting, Visual Service gives your personnel “over the shoulder support” to increase first-time fix rate and overcome terminology and language barriers.