Why Proper Aluminum Cutting Safety Protocols Can Prevent Expensive Equipment Damage

Anyone operating thermal cutting equipment for aluminum cutting knows that quality plasma, laser, and oxyfuel systems represent a substantial investment. When hundreds of thousands of dollars’ worth of cutting equipment is at stake, it’s crucial to understand why proper aluminum cutting safety protocols can prevent expensive equipment damage.

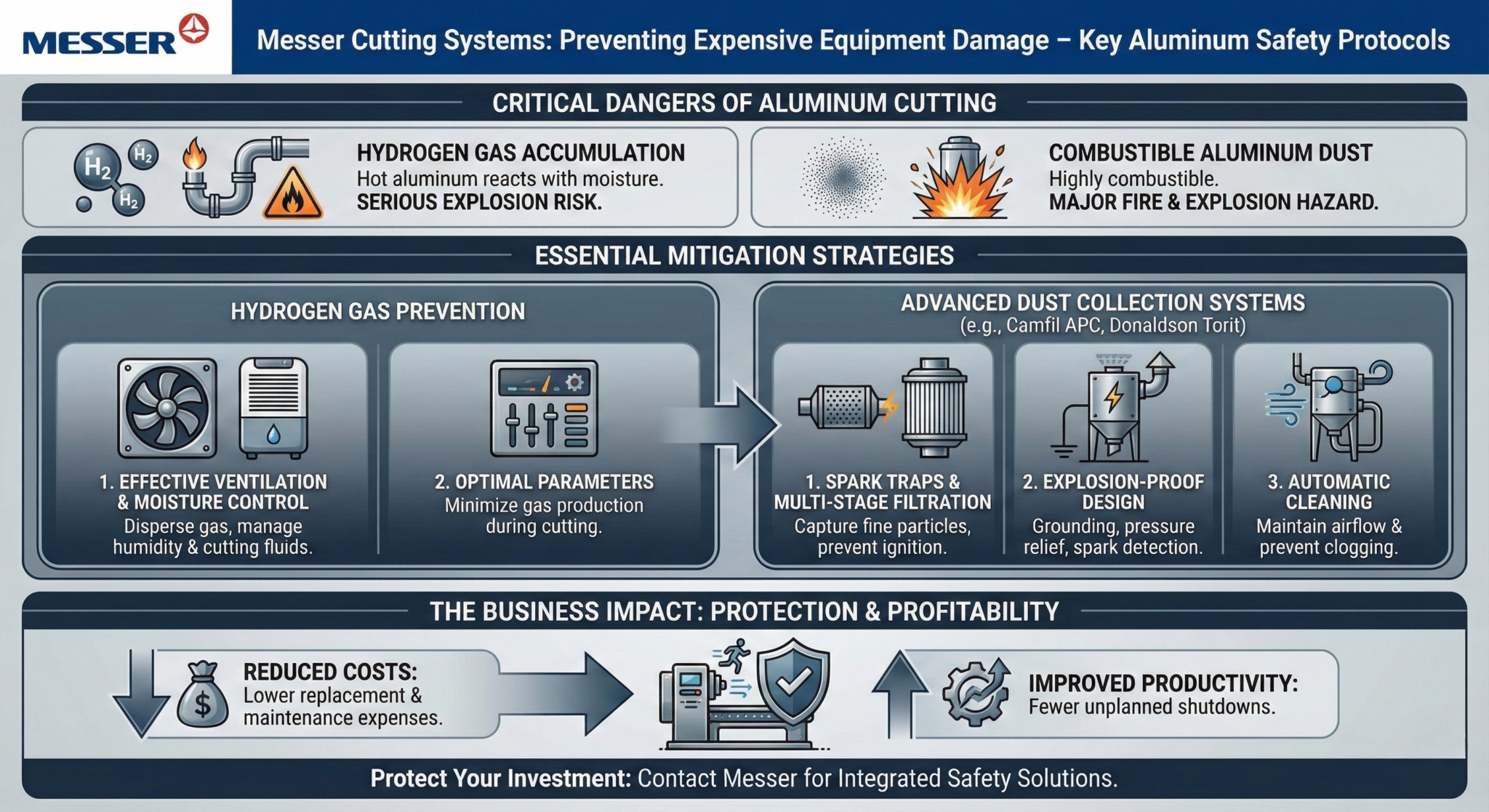

Proper safety protocols prevent equipment damage by controlling hydrogen gas accumulation, managing combustible aluminum dust, and maintaining optimal ventilation systems factors that, when mismanaged, are the leading causes of fire-related dust collector explosion.

While this answer outlines the basic mechanism of protection, several specific safety protocols vary depending on the type of thermal cutting process used, the thickness of the aluminum being cut, and the environmental conditions. Understanding these variations can mean the difference between optimal performance and catastrophic equipment damage.

The Hidden Dangers of Aluminum Cutting Operations

Understanding Aluminum’s Combustible Nature

Dust and particles generated during aluminum cutting operations are highly combustible materials that pose serious safety risks. When these fine particles accumulate without proper containment and dust removal systems, they create dangerous conditions including:

-

- Fire and explosion hazards from accumulated aluminum dust

-

- Equipment contamination leading to premature wear and failure

-

- Respiratory health risks for operators

-

- Environmental compliance issues affecting your facility’s operations

Hydrogen Gas Prevention: A Critical Safety Protocol

One of the most significant yet often overlooked safety concerns in aluminum cutting is hydrogen gas prevention. When aluminum comes into contact with moisture during cutting processes, it can generate hydrogen gas that poses serious explosion risks.

How Hydrogen Gas Forms During Aluminum Cutting

The chemical reaction occurs when:

-

- Hot aluminum particles react with water vapor in the air.

-

- Cutting fluids or coolants interact with molten aluminum.

-

- Humid environmental conditions combine with high-temperature cutting operations.

This hydrogen gas generation can lead to:

-

- Equipment damage from internal explosions.

-

- Fire hazards in the cutting area.

-

- Compromised cut quality affecting production standards.

-

- Increased maintenance costs due to equipment stress.

Implementing Effective Hydrogen Gas Prevention Strategies

Proper ventilation systems are crucial for dispersing hydrogen gas before dangerous concentrations develop. Additionally, maintaining optimal cutting parameters and using appropriate cutting technologies can minimize hydrogen gas production.

Moisture control in the cutting environment helps reduce the conditions that promote hydrogen gas formation. This includes managing humidity levels and ensuring cutting fluids are properly maintained.

Plasma Cutting Dust Collection: Essential for Equipment Protection

Dust collection systems are not optional when working with aluminum, they protect both your workforce and your cutting machinery.

Why Standard Dust Collection Isn’t Enough for Aluminum

Aluminum dust has unique characteristics that require specialized collection and filtration systems:

-

- Fine particle size that can bypass standard filters.

-

- High combustibility requires explosion-proof collection systems.

-

- Electrostatic properties that can cause dust accumulation in unexpected areas.

-

- Corrosive potential when combined with moisture.

Advanced Dust Collection Solutions for Aluminum Plate Cutting

Modern plasma cutting dust collection systems designed for aluminum applications feature:

-

- Messe Spark Traps and multi-stage filtration that captures even the finest aluminum particles before they can circulate through your facility or damage equipment components.

-

- Explosion-proof design with proper grounding and spark detection systems to prevent ignition of accumulated aluminum dust.

-

- Automatic cleaning systems that maintain optimal airflow and prevent filter clogging, ensuring consistent equipment protection.

The True Cost of Inadequate Safety Protocols

Failing to implement proper aluminum cutting safety protocols can result in:

Equipment Damage Costs

-

- Premature wear and contamination of cutting components due to dust buildup.

-

- System failures from hydrogen gas-related incidents.

-

- Calibration issues affecting cut quality and precision.

Operational Impact

-

- Unplanned downtime for equipment cleaning and repairs.

-

- Reduced productivity due to safety incidents.

-

- Quality control problems affecting customer satisfaction.

-

- Regulatory compliance costs and potential fines.

Hidden Expenses

-

- Increased insurance premiums following safety incidents.

-

- Worker compensation claims related to exposure incidents.

-

- Environmental remediation costs from improper dust management.

-

- Lost contracts due to safety record concerns.

Implementing Comprehensive Safety Protocols

Effective aluminum cutting safety requires a systematic approach that addresses all aspects of the cutting operation:

#1 Pre-Cutting Safety Preparation

-

- Equipment inspection to ensure all safety systems are functioning.

-

- Environmental assessment of humidity and ventilation conditions.

-

- Material preparation to minimize moisture content.

#2 During Cutting Operations

-

- Continuous monitoring of dust collection system performance.

-

- Regular ventilation checks to ensure proper hydrogen gas dispersal.

-

- Parameter optimization to minimize particle generation.

-

- Emergency response readiness for any safety incidents.

#3 Post-Cutting Safety Procedures

-

- Thorough cleaning of work areas to remove aluminum residue.

-

- System maintenance to ensure continued safety performance.

-

- Documentation of any safety-related observations.

-

- Equipment inspection for signs of contamination or damage.

Advanced Safety Technologies for Modern Aluminum Cutting

Today’s cutting systems incorporate sophisticated safety features specifically designed for aluminum applications:

#1 Integrated Dust Collection Systems

Modern cutting tables feature built-in dust collection capabilities that capture particles at the source moves those particles to the dust collector which prevents contaminating equipment or creating workplace hazards.

#2 Smart Monitoring Systems

Advanced control systems can monitor environmental conditions and automatically adjust cutting parameters to minimize hydrogen gas generation and optimize dust collection performance.

#3 Automated Safety Protocols

Intelligent cutting systems can implement safety shutdowns when dangerous conditions are detected, protecting both equipment and personnel from potential hazards.

Choosing the Right Equipment for Aluminum Cutting Safety

When selecting cutting equipment for aluminum applications, prioritize systems that offer:

-

- Dust Collection Systems Messer Cutting Systems offer is Camfil APC and Donaldson Torit.

-

- Comprehensive dust collection integration with explosion-proof design and multi-stage filtration capabilities.

-

- Advanced ventilation capabilities that effectively manage hydrogen gas and other combustible vapors.

-

- Intelligent control systems that optimize cutting parameters for safety and quality.

-

- Easy maintenance access for regular cleaning and safety system maintenance.

The Business Case for Proper Safety Investment

While implementing comprehensive aluminum cutting safety protocols requires upfront investment, the long-term benefits far outweigh the costs:

Return on Investment Factors

-

- Reduced replacement costs through better protection.

-

- Lower maintenance expenses due to cleaner operating conditions.

-

- Improved productivity from fewer safety-related shutdowns.

-

- Enhanced reputation leading to new business opportunities.

Competitive Advantages

-

- Superior cut quality from optimized, safe cutting conditions.

-

- Faster turnaround times due to reliable equipment operation.

-

- Customer confidence in your safety and quality standards.

-

- Regulatory compliance avoiding costly violations and fines.

Building a Culture of Safety Excellence

Effective aluminum cutting safety extends beyond equipment it requires developing a comprehensive safety culture throughout your organization.

Training and Education

Regular training programs ensure all personnel understand the unique safety requirements for aluminum cutting operations and can recognize potential hazards before they become problems.

Continuous Improvement

Ongoing evaluation and improvement of safety protocols help identify new opportunities to enhance protection and prevent equipment damage.

Industry Best Practices

Staying current with evolving safety standards and industry best practices ensures your operations remain at the forefront of aluminum cutting safety.

Protecting Your Investment Through Safety

Investing in advanced cutting systems with integrated safety features provides the foundation for safe, efficient, and profitable aluminum cutting operations. When safety becomes a core operational principle, you’re not just protecting your workforce you’re safeguarding your business’s future profitability, and equipment protection naturally follows.

Contact Messer Cutting Systems to learn about our advanced aluminum cutting solutions with integrated safety features that protect both your equipment and bottom line.