Messer Cutting Systems’ machines offer a range of cutting options, with fiber laser (straight) and fiber laser plasma combination having emerged as the favored choices among businesses.

Because of its small focus spot, laser cutting is known for its high accuracy.

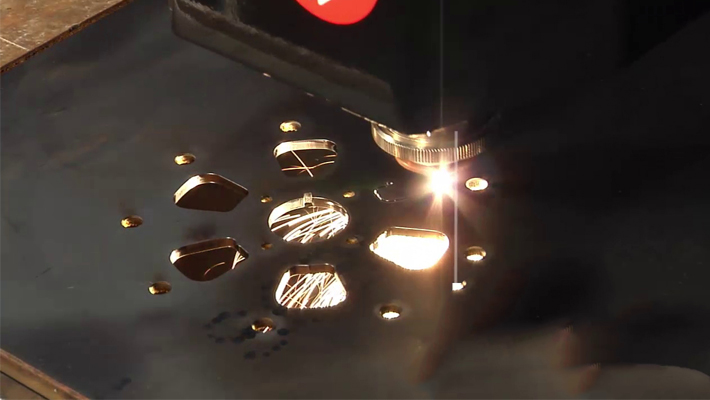

With laser cutting, a laser beam is focused on the material through a nozzle’s hole, heating and melting the material. A cutting gas that flows coaxially through the nozzle removes the molten material.

Three Types of Laser Cutting

There are three types of laser cutting that exist. These are sublimation cutting; flame-cutting, also known as oxygen cutting; and fusion cutting.

Sublimation Cutting

With sublimation cutting, a laser beam brings the material to its vaporization point directly in a process that is called sublimation. An inert, or inactive, cutting gas—such as nitrogen, helium, or argon—forces the molten material out of the cut piece part.

During the sublimation cutting process, the material changes directly from the solid to the gaseous state with as little melting as possible. The cutting gas keeps the particles and vapors away from the optical elements.

To vaporize metal requires more energy than to melt it. Thus, sublimation cutting demands significant laser power and is generally slower compared with other cutting processes. This extra energy, however, delivers cuts of very high quality.

Flame Cutting & Oxygen Cutting

With flame cutting, also known as oxygen cutting, a material is heated only to its ignition temperature. Oxygen is used as cutting gas so that the material burns and forms a pure stream of oxide that melts through the additional energy from burning. The cutting oxygen then forces the slag out of the cut piece part.

Typical materials used in flame cutting, or oxygen cutting / Oxyfuel, are low-alloy steel, also referred to as mild steel stainless or aluminum, and cast irons.

With flame cutting, the material’s ignition temperature must be below the melting point. With high-alloyed steels and nonferrous metals, flame-cutting with oxygen is feasible but, for qualitative and economic reasons, it is not ideal.

Fusion Cutting

With fusion cutting, the material is heated by the laser beam up to the melting point and forced out of the kerf by a high-pressure stream of cutting gas (up to 25 bar). As with sublimation cutting, an inert gas, usually nitrogen, is used to force the molten material out of the cut.

In special cases, argon is the inert gas that is used. This is the case, for example, with magnesium, tantalum, titanium, and zircon because these materials form chemical bonds with nitrogen.

Materials that are unsuitable for flame cutting are cut using the fusion cutting process. Materials that are typically used include alloyed steels, also known as stainless steel.

For quality reasons, fusion cutting can also be utilized to cut unalloyed and low-alloyed steels. This creates oxide-free cutting surfaces, but cutting speeds are considerably slower.

Laser Characteristics:

- Max cut capacity, 1.5″ (38.1mm) mild steel, 1″ (24.5 mm) stainless and aluminum. * Capacity determined by select wattage.

- Fiber lasers from 4kW to 20kW.

- Fiber laser bevel cutting and bevel cutting machines.

Key features:

- Laser light can be well focused ca. 0.2 mm.

- Very high power density (some MW/cm2).

- High to medium cut quality (roughness).

- Metallurgical perfect surfaces (oxidized) or metallically blank surfaces (high pressure inert gas cutting).

- Low heat input.

- Hardening within the area of the heat-affected-zone (HAZ) with hardening.

Whether sublimation cutting, flame-cutting, or fusion cutting is used, because of a laser beam’s narrow focus, the width of the cut, or kerf width, is very small compared with other thermal cutting processes. Thus, minimum material is melted, and the laser energy is used very efficiently. The material’s heat input is relatively low so that even small geometries can be cut.

Additionally, the cut edge is relatively straight, providing very high component accuracy from the cutting process. This means that laser cutting is used in the most diverse areas, especially whenever the high accuracy of the component geometry and cut edge are required. The preferred range for steel sheets is up to a material thickness of 20 millimeters. Under certain circumstances, however, this range can extend up to 25 millimeters.

With laser cutting, fiber laser (straight), fiber laser beveling, and fiber laser / plasma combination lasers are typically used. With greater material thicknesses, however, laser cutting makes sense for only special applications, more usually other cutting processes (oxyfuel or plasma cutting) are used here.

To gain even more flexibility, laser cutting can be combined with plasma cutting.

Contact

Messer Cutting Systems, Inc.

The Ultimate Guide

Getting Started with Laser Cutting Machines

Laser cutting is a fabrication process that utilizes a high-powered laser beam on a laser cutting machine to cut the material into various shapes and designs. The laser cutting process is suitable to cut a wide range of materials including metal, plastic, wood, gemstone, glass, and paper. A key benefit of laser cutting is that this process can generate precise and complex parts without any need for custom-designed tooling.

Several types of laser cutting machines are available, with each specific process producing parts with a high degree of precision, accuracy, and high-quality edge finishes. The laser cutting process generally results in less material contamination, physical damage, and waste compared with many other common cutting processes.

Messer Cutting Systems offers fiber laser (straight cutting) machines, fiber laser beveling machines, and fiber laser/plasma combination machines. Learn More.

Cutting options

Fiber Laser (Striaght)

Fiber laser (straight) delivers high accuracy cuts with low heat input. Messer Cutting Systems’ 4,000kW to 20,000kW fiber laser also offers low maintenance and high efficiency.

With fiber laser, a laser beam is guided via a fiber cable, with no adjustment necessary between laser source and carriage. Additionally, no purging gas is required.

With a wall plug efficiency of as high as 30 percent, the fiber laser is much more efficient than some other counterparts. The cutting quality in mild steel is comparable up to 15 mm thickness. Stainless steel and aluminum are also possible.

Thus, the fiber laser is a flexible and easy tool that also offers high accuracy and low heat input.

Fiber Laser / Plasma Combination

Messer Cutting Systems’ fiber laser/plasma combination makes use of a fiber optic cable for beam delivery and can be used in conjunction with the plasma process. By eliminating the need for mirrors, cleaning, alignment and replacement of mirrors are all unnecessary.

The fiber laser process is three times more efficient compared to some other lasers, eliminating the need for a resonator. With no laser gas required, operational costs are considerably less.

Bevel Laser Cutting

Bevel cutting calls for a precise knowledge of the laser machine and the cutting processes. Corners, lead-ins and run-outs must be cut in a special sequence to achieve the desired quality.

Bevel cutting also places significant demands on the cut parts’ programming. Special auxiliary functions are needed to set up the units for laser bevel cutting.

SUITABLE Machines

Messer Cutting Systems’ Element 400 L Unitized, FiberBlade V, and MetalMaster Xcel unitized cutting machine are choice laser cutting machines, offering customers high speed and precision accuracy. Ask about material handling solutions as well.

Element 400 L Unitized

The new Element 400 L unitized cutting machine comes in 6′, 8′, or 10′ widths with 10′ to 40′ in length. Designed for strength, durability, and precision the machine offers fiber laser bevel cutting with the Bevel-U. This machine also offers fiber laser/plasma cutting combination cutting.

Fiber Blade V

Compact 5′ x 10′ straight fiber laser cutting machine including enclosure offers an economical solution to fiber laser cutting. This machine comes with a pallet shuttle table perfect for material handling solutions. Learn More.

MetalMaster Xcel

MetalMaster Xcel delivers fast operating sequences, outstanding cutting quality, and peerless accuracy. Cutting widths for 6’, 8’, and 10’ and lengths from 10’ to 55’ in 5’ increments. The Messer Slagger® self-cleaning table comes standard on the Xcel.

Beyond the fiber laser/plasma combination cutting processes, this machine offers additional tools such as material handling, drilling, and markers and so much more. Enclosure required for operator safety.