Expert Insights: How Can Predictive Maintenance Reduce CNC Cutting Machine Downtime?

For manufacturing operations, unexpected CNC machine downtime can result in thousands of dollars per hour in lost production, making it one of the most costly problems to resolve in a machine shop. So, how can predictive maintenance reduce CNC cutting machine downtime?

Predictive maintenance CNC can reduce CNC cutting machine downtime by up to 50% by using sensors and data analytics to detect potential failures before they occur, allowing maintenance to be scheduled during planned downtimes

While this answer may seem straightforward, several critical components of a predictive maintenance program must be properly implemented to achieve these results. Understanding these elements can mean the difference between success and failure in reducing machine downtime.

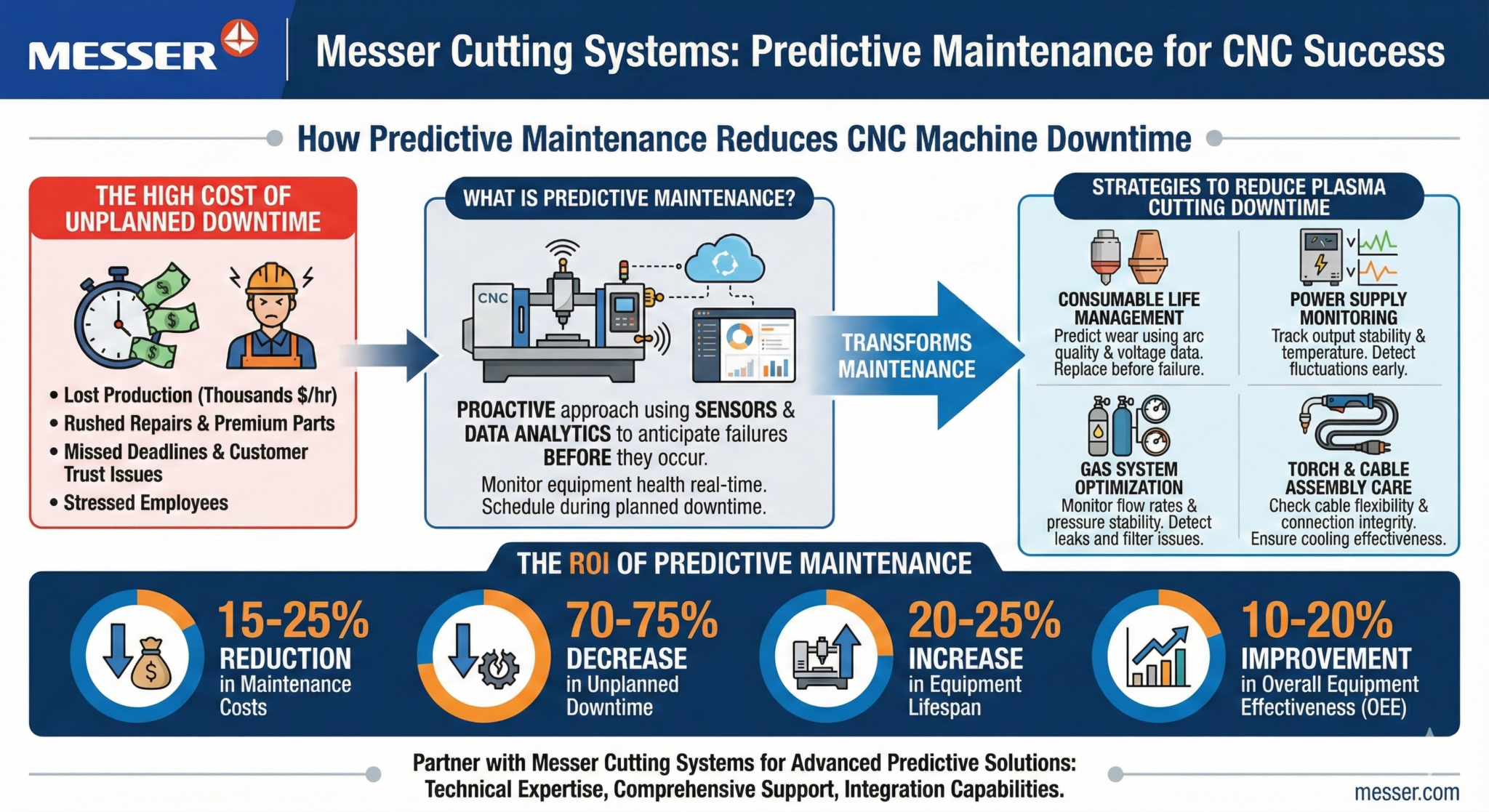

The High Cost of Unplanned Downtime in Manufacturing

The statistics behind CNC machine downtime are sobering. As highlighted in Industry Week’s breakdown of modern maintenance strategies, manufacturers are increasingly recognizing that reactive repairs and traditional scheduled maintenance often fall short in preventing these costly disruptions. Every minute your cutting equipment is offline creates a cascade of problems that can impact delivery schedules, customer relationships, and your company bottom line. That often results in:

- Rushed repairs that often cost more than scheduled maintenance.

- Missed delivery deadlines that damage customer trust.

- Overtime labor costs to catch up on production.

- Emergency parts procurement at premium prices.

- Stressed employees working under pressure to restore operations.

For manufacturers relying on plasma cutting, laser cutting, or oxyfuel cutting processes, even a few hours of unexpected downtime can translate to thousands of dollars in losses.

What is Predictive Maintenance for CNC Systems?

Predictive maintenance for CNC is a proactive approach that utilizes data analysis and monitoring technology to anticipate when equipment failures are likely to occur.

Instead of waiting for machines to break down or following rigid preventive maintenance schedules, predictive maintenance allows you to:

- Monitor equipment health in real-time.

- Identify potential issues before they cause failures.

- Schedule maintenance during planned downtime.

- Optimize maintenance intervals based on actual machine condition.

This data-driven approach transforms maintenance from a reactive cost center into a strategic advantage that maximizes equipment availability and performance.

Learn more about our 360° Service solutions here.

How Machine Monitoring Systems Transform Maintenance

Modern machine monitoring systems are the backbone of effective predictive maintenance programs. These sophisticated systems continuously collect and analyze data from your cutting equipment, including:

- Vibration patterns that indicate wear or misalignment.

- Power consumption trends that reveal efficiency changes.

- Cutting quality metrics that signal tool or system degradation.

- Operating hours and cycle counts for wear prediction.

Advanced Analytics Capabilities:

Machine monitoring systems use artificial intelligence and machine learning algorithms to:

- Establish baseline performance patterns.

- Detect anomalies that may indicate developing problems.

- Predict failure timelines with increasing accuracy.

- Recommend optimal maintenance timing and procedures.

Strategies to Reduce Plasma Cutting Downtime

Plasma cutting systems face unique challenges that make predictive maintenance particularly valuable. Here’s how to reduce plasma cutting downtime through targeted monitoring and maintenance strategies:

1. Consumable Life Management

Plasma cutting consumables (electrodes, nozzles, shields) wear predictably but at varying rates depending on:

- Material thickness and type.

- Cutting speed and amperage.

- Gas quality and flow rates.

- Environmental conditions.

Predictive approach: Monitor arc quality, voltage patterns, and cut quality metrics to predict when consumables need replacement, ordering parts before they fail rather than after.

2. Power Supply Health Monitoring

The power supply is critical to plasma cutting performance. Key monitoring points include:

- Output stability and consistency.

- Internal temperature management.

- Capacitor health and charging cycles.

- Transformer performance metrics.

Early warning signs: Voltage fluctuations, temperature spikes, or power output inconsistencies often precede major failures.

3. Gas System Optimization

Plasma cutting relies on precise gas flow and pressure. Monitoring systems should track:

- Gas consumption rates and efficiency.

- Pressure stability across the system.

- Filter condition and replacement needs.

- Leak detection throughout gas lines.

4. Torch and Cable Assembly Care

The plasma torch and cable assembly endure significant stress. Predictive maintenance monitors:

- Cable flexibility and electrical continuity.

- Torch alignment and wear patterns.

- Connection integrity and resistance.

- Cooling system effectiveness (for high-amperage systems).

Options for Implementing Predictive Maintenance: Step-by-Step Tips for your cutting equipment:

Assessment and Planning

- Audit current equipment and identify critical failure points.

- Evaluate existing maintenance practices and costs.

- Define success metrics for your predictive maintenance program.

- Select appropriate monitoring technologies for your specific equipment.

Technology Integration

- Install sensors and monitoring devices on critical components.

- Integrate data collection systems with your existing infrastructure.

- Configure alerts and thresholds based on Messer recommendations.

- Train maintenance staff on new procedures and technologies.

Data Analysis and Optimization

- Establish baseline performance patterns for each machine.

- Refine predictive algorithms based on actual failure data.

- Optimize maintenance schedules using machine insight.

- Continuously improve predictions based on outcomes.

The ROI of Predictive Maintenance

Companies implementing comprehensive predictive maintenance programs typically see:

- 15-25% reduction in maintenance costs.

- 70-75% decrease in unplanned downtime.

- 20-25% increase in equipment lifespan.

- 10-20% improvement in overall equipment effectiveness (OEE).

For a typical industrial cutting operation, these improvements can represent hundreds of thousands of dollars in annual savings and productivity gains.

Advanced Technologies Driving Predictive Success

Internet of Things (IoT) Integration

Modern cutting machines increasingly feature built-in IoT capabilities that enable:

- Remote monitoring and diagnostics.

- Cloud-based data analysis and storage.

- Integration with enterprise resource planning (ERP) systems.

- Mobile alerts and dashboard access capabilities are further enhanced by the rise of industrial 5G connectivity.

The Future of Artificial Intelligence and Machine Learning

AI-powered predictive maintenance systems continuously improve their accuracy by:

- Learning from historical failure patterns.

- Identifying subtle correlations in multi-variable data.

- Adapting predictions based on changing operating conditions.

- Providing increasingly precise maintenance recommendations.

The Future of Digital Twin Technology

Creating digital replicas of physical cutting systems allows for:

- Virtual testing of maintenance scenarios.

- Simulation of failure conditions.

- Optimization of operating parameters.

- Enhanced training for maintenance personnel.

Choosing the Right Predictive Maintenance Partner

Let Messer Cutting Systems service staff help you with predictive maintenance for your cutting operations, consider the following.

#1 Technical Expertise

- Deep understanding of thermal cutting processes.

- Experience with plasma, laser, and oxyfuel technologies.

- Proven track record in industrial automation.

#2 Comprehensive Support

- Initial system design and installation.

- Ongoing training and technical support.

- Regular system updates and improvements.

- Emergency response capabilities.

#3 Integration Capabilities

- Compatibility with existing equipment and systems.

- Scalable solutions that grow with your operation.

- Open architecture for future technology adoption.

From Reactive to Predictive Success

Predictive maintenance CNC strategies represent a fundamental shift from reactive to proactive equipment management. By leveraging advanced machine monitoring systems and data analytics, Messer can dramatically reduce plasma cutting downtime while optimizing maintenance costs and extending equipment life.

The key to success lies in choosing the right combination of technology, training, and support partners. As cutting operations become increasingly sophisticated and competitive pressures intensify, predictive maintenance is no longer just an option; it is essential for achieving operational excellence.