Shipbuilding and ShipYards

The shipbuilding industry and the construction of ships and other floating vessels that takes place in a shipyard. It is one of the largest, most complex, and most competitive industries in the world. This industry has a great impact on social and economic standing throughout the world. It is a constantly growing and competitive industry that relies on innovative and precision cutting technology. Messer Cutting System supplies shipyard customers with precision cutting technology with laser, oxyfuel, and plasma cutting systems that are crucial to advancing the shipbuilding industry.

Building the Ocean’s Giants

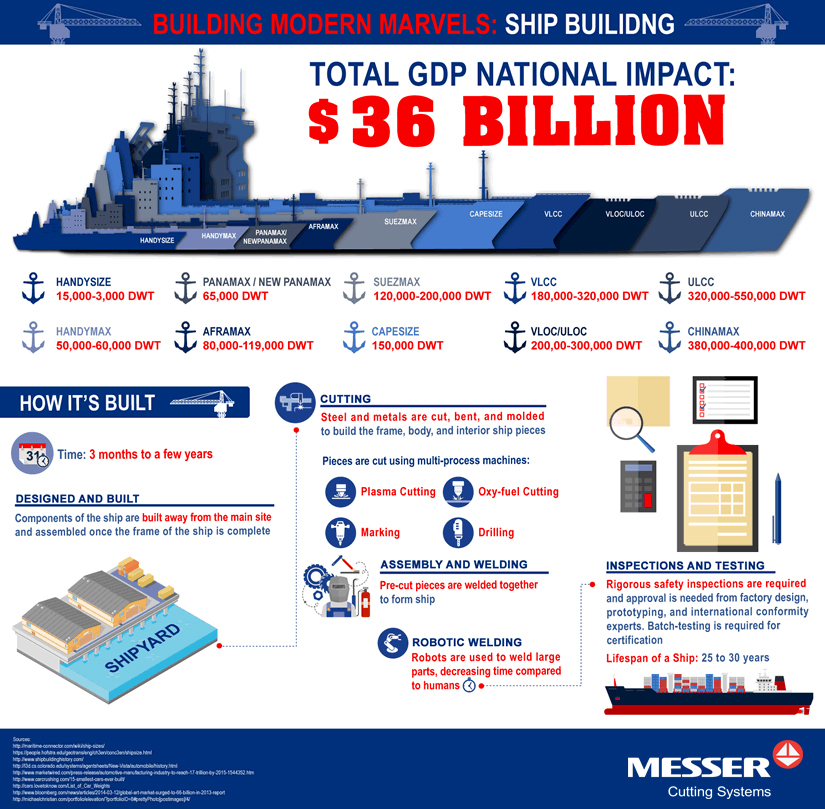

Building some of the largest, most complex, industrial mid-size ship building projects can take roughly 18 months on average to build and complete. To make the building process more efficient, components of the ship are built at a secondary location, usually a shipyard. These pieces are cut, welded, and assembled once the frame of the ship is complete. Messer’s CNC cutting machines are used to cut the long frame, body, and complex shapes within the interior of the ships.

Ships are one of the largest man-made products used to carry tons of cargo through open waters across the globe. Because of this, ships need to be held to strict and rigorous safety codes. Ships are thoroughly inspected and cleared during each process of the building process to ensure maximum safety and must pass certification before they can set sail. Ships are built to last, and most ships have a lifespan of up to 30 years, thanks to the quality craftsmanship of the shipbuilding process.

SHIP BUILDING INFOGRAHIC

Messer Cutting Systems, Inc.

Case Study

Shipbuilders Rely on Messer

Messer Cutting Systems heavy-duty cutting machines can be found in shipyards worldwide providing precision cutting technology. By using Messer’s diverse cutting systems, the shipbuilding industry has grown and continues to bring in an average of $36 billion each year.

Messer Slagger® tables are used to strip cut and bevel cut aluminum, mild steel, and stainless plate on tables that are over 200 ft. long. Beveling cutting plates on long tables makes it easier to bend and weld plates at the bevel seamlessly. We also offer optional bevel and straight pipe cutters for ships interior pipes needed within ships.

For more information about Messer Cutting Systems in the shipbuilding industry or to speak to one of our certified experts, call us today at 262-255-5520.

MPC2000 MC

- Plasma and oxyfuel straight and bevel cutting.

- Drilling up 2.5″ diameter. Tapping up to 1.5″.

- Chip vacuum collection system.

- Markers.

- Pipe bevel cutting.

- Tables widths 12′ to 28′.

- Table lengths up to 200′.

TMC4500 DB

- Plasma and oxyfuel straight and bevel cutting.

- Drilling up 4.0″ diameter. Tapping up to 1.5″.

- Markers.

- Pipe bevel cutting.

- Tables widths 12′ to 28′.

- Table lengths up to 200′.