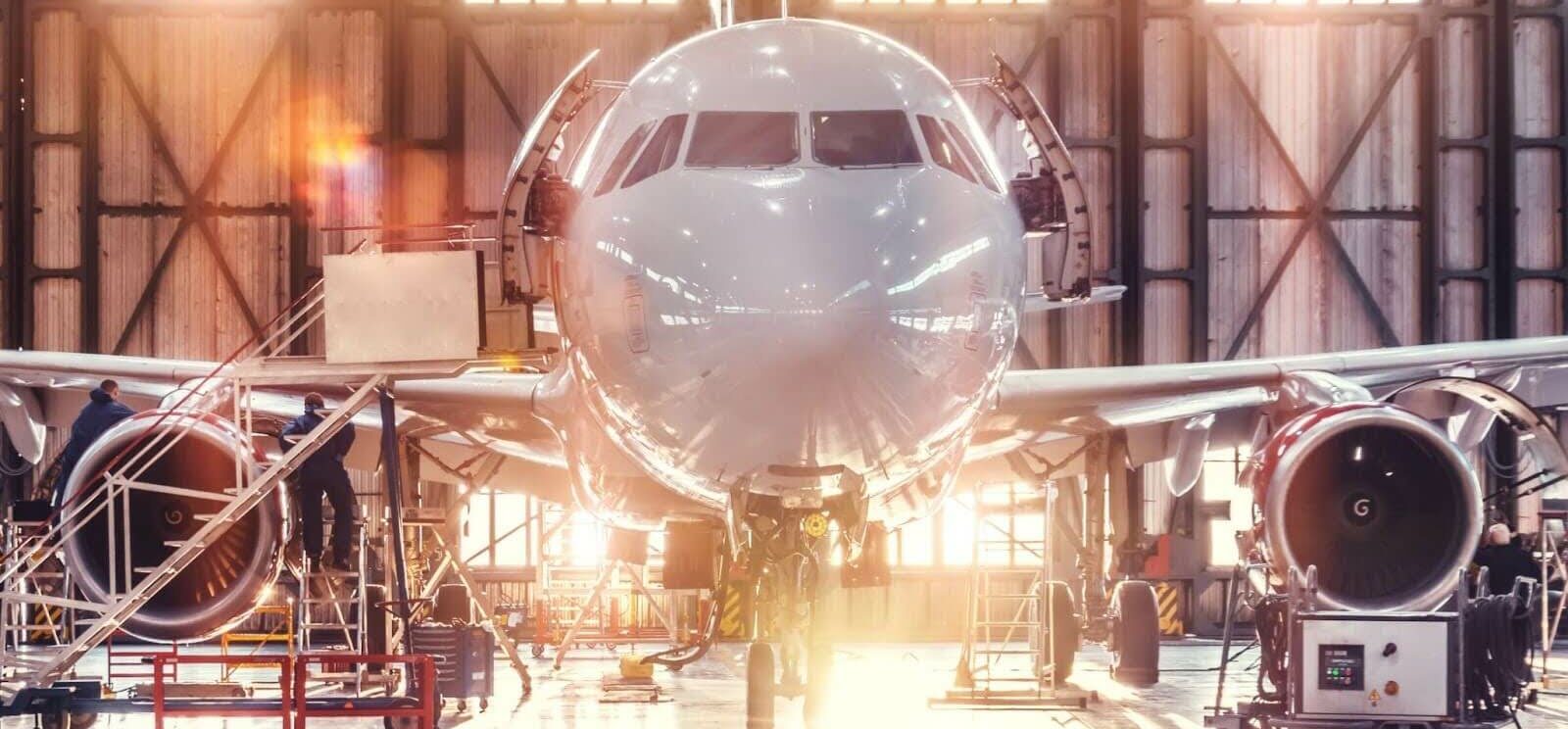

Cutting Solutions for Aerospace and AVIATION Manufacturing

Advanced cutting machines and systems from Messer provide aviation manufacturers the latest technology needed to produce precision quality components and precision cut parts efficiently. Messer’s innovative solutions enable aircraft and spacecraft builders to achieve “new heights” in manufacturing.

The aviation industry rely on precision laser cutting machines and advanced automation solutions. Suppliers demain heavy-duty aluminum sheet plate bevel cut to exacting standards. These plates are seamed and welded perfectly to assemble airplanes that to withstand the daily wear for various weather conditions including weight, thrust, lift and drag.

With the aerospace industry heavy-duty plasma bevel cutting machines are used to cut heavy duty parts in the manufacture of rockets, rocket lift launch pads and crawler-transporter platform movers. Messer machines also cut steel to handle extreme heat and extreme cold of conditions space. Cut parts are also used to manufacture satellites and its components. These public and private aerospace companies rely on Messer Cutting Systems.

How Messer Automation Improves AVIATION Manufacturing

Integrating Messer’s cutting-edge automation software and material handling solutions into aviation manufacturing delivers major enhancements across all of cutting production. Messer technology helps boost your factory’s productivity in a cost-effective, efficient, transparent way. See how Industry 4.0 can being productive across the whole value chain can benefit your company or shop.

OMNIFAB CUTTING SOFTWARE MADE FOR HIGH PRODUCTION

Data-Driven Forecasting and Planning

Messer software generates real-time data for optimizing production, allowing you to track inventory levels, material usage, and order trends for data-driven forecasting. Better align your output of aerospace parts with actual demand. Learn more about OmniFab software.

Reduced Downtime

Automated workflows and material handling minimize interruptions, reducing downtime and ensuring maximum productivity. Many of our machines are designed for continual 24/7 operation, allowing you to increase production around the clock. All of this can be achieve with Omnifab Software.

Advanced Software Integration

Messer systems seamlessly connect for a streamlined process. Our Industry 4.0 software solutions centralize cutting, inventory tracking, and machine monitoring for a fully integrated solution.

Material Handling Automation

Automated material movement improves factory flow. Our cutting machines enhance your material handling processes; from in-line cutting solutions to fully-automated retrieval and storage systems, integrating Messer technology will increase your efficiency and productivity to meet the demand of the aviation / aerospace industries.

Higher Output and Efficiency

Maximize uptime for continuous, high-volume production with Messer cutting machines. Optimized cutting programs allow for higher output rates with excellent cut quality for larger quantities of high-precision stainless steel and aluminum cut parts. Ask us about shuttle tables, and material handling solutions.

Supplying the Machines You Need to Produce Quality AVIATION and Aerospace Cut Metal Parts

Messer’s full range machines engineered specifically to produce aircraft, planes spacecraft, rockets, and all related components for fabrication. Some of our top solutions for the aerospace and aviation industries include:

MetalMaster Xcel

Precision straight laser cutting also plasma cutting both bevel and straight. Suited for the aviation industry.

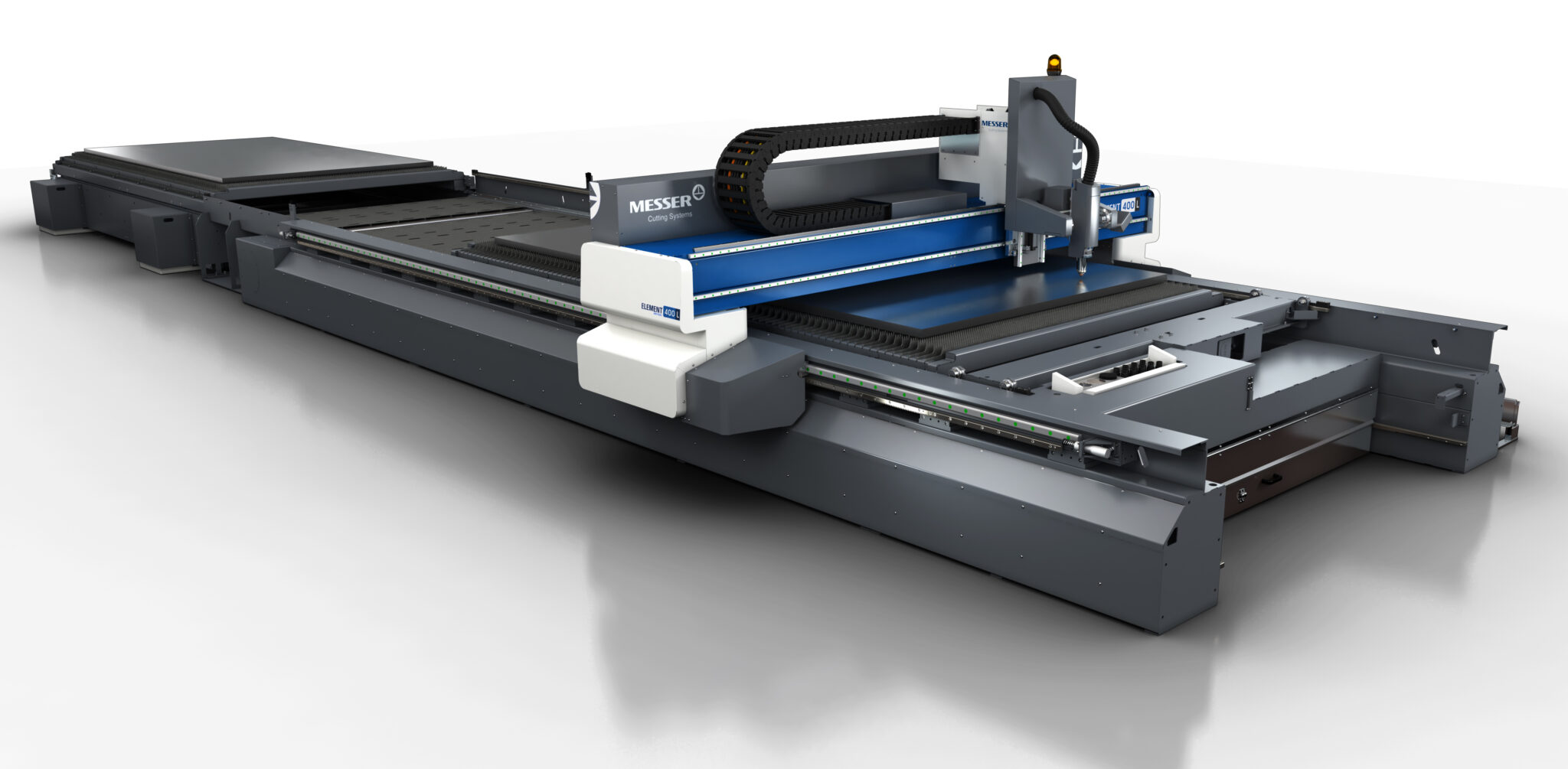

Element 400 L Unitized

The latest in the new equipment and technology for precision laser beveling up to 50 degrees and perfectly suited for material handling.

Achieve Optimal Avaionic Part Performance with Cutting Solutions from Messer

Messer’s cutting-edge technology enables aerospace manufacturers to achieve the high standards of precision, quality, and performance required in the industry. Messer machines optimize efficiency while maintaining tight tolerances and superior finishes. This empowers aerospace builders to fabricate highly durable components that withstand extreme conditions.

Aircraft and Spacecraft Structural Components

Messer machines precision cut aluminum, titanium, and composite materials to fabricate fuselages, wings, doors, interior panels, and other structures with tight tolerances.

Engines and Propulsion Systems

Our plasma, laser, and oxyfuel cutters rapidly fabricate engine and thruster housings, turbines, nozzles, and combustion chambers from high-temp alloys.

Avionics Components

Messer machines reliably cut aluminum and stainless steel sheets for avionics housings, brackets, instrument panels, and electronic enclosures.

Landing Gear and Wheels

Strong, fatigue-resistant landing gear, wheels, and struts can also be produced with Messer’s heavy plate processing machines.

The FUTURE OF Aviation and Aerospace Manufacturing

The aerospace industry outlook remains positive for the foreseeable future. Factors contributing to this outlook include increasing demand for commercial aircraft and rising focus on aerospace research and development.

The growing need for lightweight and fuel-efficient airplane components requires advanced laser cutting machines, which Messer is proud to offer.

Contact Us to request a quote for a cutting machine.