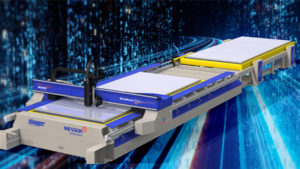

Titan III Plasma Cutter

The Titan III was designed for demanding environments. Utilizing an innovative end truck design, which houses and isolates the electronics away from the plate processing area, the Titan III can easily handle both heavy plate and around-the-clock operation.

The machine features linear ways in the Y-axis, pitch-line engaged rack and pinions, and our high productivity SL lifters for smooth, repeatable cutting or marking. Our industry-leading Global ControlPlus lets you cut faster with our easy-to-use touch screen interface utilizing the latest software.

Why Does Messer Cutting System Manufacture the Titan III Plasma Cutters?

Through close partnership with our customers like you, the Titan III is the machine that you helped design. It is a mid-sized and industrial-grade workhorse supporting the hard-working men and women that power American industry. With over 750 Titans installed in the United States, they can be found in nearly every metal industry, and their reliability has made them popular with a multitude of OEMs and steel service centers.

The Titan III is available with many standard tools. Choose from vertical plasma, oxyfuel, or bevel cutting, as well as drilling up to 1/2″, and your choice of a variety of permanent and semi-permanent marking options. No matter the metal type or thickness, we have a plate metal-cutting solution to move your business forward.

Titan III Machine Specifications

- Cutting widths: 6′ to 16′ (1.82 m to 4.876 m).

- Cutting lengths: up to 150′ (45.72 m).

- Type of Control: Messer Global ControlPlus CNC Control

- Contouring Speeds: 400 IPM

- Positioning Speeds: Up to 1,700 IPM

- Machine Motion Accuracy: +/- .010″ (.254 mm)

- Machine Motion Repeatability: +/- .010″ (.254 mm)

- Material Cutting Capability: 26 gauge to 12″ plate thickness

Contact

Messer Cutting Systems, Inc.

Downloads

Titan III Components

Messer offers a variety of process tools. All Messer machines are completely customized. The benefits of a customized cutting machine fit for your company’s needs can make you the leader of productivity in your industry. When you need a machine that outperforms all others and provides you with the capability of bevel cutting, drilling, tapping, and marking, all on a variety of materials from thin plate to thick steel with an excellent cut part quality, then Messer Cutting Systems is your machine of choice.

Alfa

The Messer Cutting Systems developed ALFA oxy-fuel torch takes oxy-fuel cutting to an entirely new level. The ALFA torch internalizes many features that used to have to be on the outside of an oxy-fuel torch, including height sensing and auto-ignition.

MS 832/Turbo Torch

Our Turbo Flame™ Torch is very versatile, able to be used with a variety of fuel gases and is very safe to operate.

FT100 Torch Ignitor

Messer Cutting Systems FT100 Torch Ignitor remotely ignites any brand of oxyfuel torch. Since no arc is struck, critical alignment is not needed allowing for easy and fast tip change out.

Omniflow Automatic Gas Control System

The Omniflow Automatic Gas Control System delivers automatic setting and regulation of preheat oxygen, cutting oxygen and fuel gas pressure during oxyfuel cutting.

Single Position Oxyfuel Bevel Unit

Manually adjusted Single Position Triple Torch Oxy-fuel Bevel Unit for straight line bevels with manual ignition and gas adjustment.

Three Position Oxyfuel Bevel Unit

Manually adjusted Triple Torch Oxyfuel Bevel Unit for straight line bevels with manual gas adjustment and manual ignition.

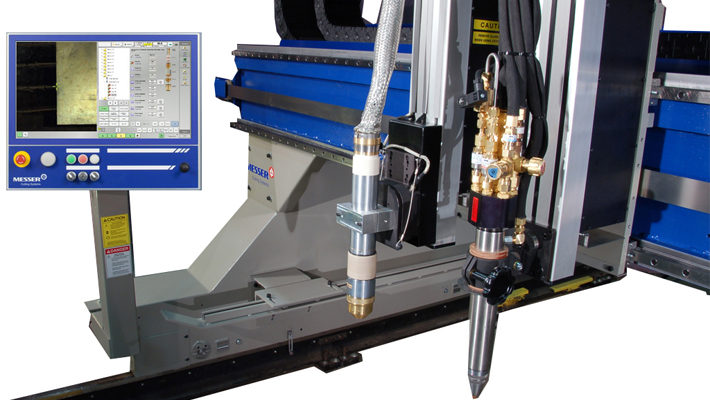

Straight Plasma Cutting

Our products cover the whole range of cutting tasks in modern metal industries. Using different thermal cutting technologies for straight plasma cutting, our machines can be easily adapted to your shop’s requirements.

Global Rotator Delta e Bevel Cutting

Robust compact design, coupled with our OmniBevel software, creates the best plasma bevel cut parts.

Manual Plasma Stripping Bevel Unit

Messer Cutting Systems’ Manual Plasma Bevel Unit provides an adapter mounting between the SureStop breakaway and the lifter. This component enables straight-line motion bevel cutting in the X-axis.

Air Scribe Marking

The Air Scribe marker uses a reciprocating pin to mark on mild steel, stainless steel, and aluminum plate. The marker can be used with any plate thickness.

Plasma Marking

Plasma marking is suitable for the engraving of lines, contours and characters on plate surfaces.

Inkjet Marking

Ink-jet marking delivers fast and quiet alphanumeric labeling with printing in one direction of travel for non-rotational unit or multi-directional with rotating unit.

Telesis Pinstamp®

The Telesis® Pinstamp® marking system uses a reciprocating stylus permanently prints messages on to a variety of plate such as mild steel, stainless steel, and aluminum.

Electric Drilling Unit

An optional drill feature can be combined with a normal plasma and oxyfuel cutting, allowing for form work to be done on the piece part in a single handling.

SL-200, SL-300 Plasma and Oxyfuel SmartLifters

The SL200 PLASMA AND OXYFUEL SMARTLIFTERS include several productivity enhancing features to produce more parts in a shorter period of time. An adaptive initial height sense system “learns” the height of the plate on the cutting table to quickly position the torch to the correct pierce height.

PL-1 Lifter with Surestop Collision Sensor

Messer Cutting Systems’ PL-1 Plasma Torch Lifter combines plasma arc voltage monitoring with a CNC closed-loop positioning axis to significantly enhance plasma height control in plasma cutting. This enhanced height control results in a higher duty cycle and better cut quality. The Surestop Collision sensor for fast and easy torch reset.

SensoMat®-PAN

SensoMat®-PAN Height Sensing for oxyfuel reliably maintains the proper standoff distance between the oxyfuel torch tip and the work piece, without operator intervention.

Laser Pointer

Our Laser Pointer enables the operator to identify the edge or other feature of the plate physically with a known location on the cutting machine, simplifying the basic setting, shortening throughput times and avoiding scrap.

Digital Video Camera

Monitor the cutting process with Messer Cutting Systems’ Digital Video Camera. This product assists in remote diagnostics using Virtual Service™ and gives your team the benefit of having a bird’s-eye view of the cutting process.

Plasma Air Booster

Plasma air booster is a low cost alternative to an expensive air compressor. Available for all machines with a plasma system.150 PSI per CFM.

Dual Hi-Lo

Dual Hi-Lo Manual Gas Control System is an economical gas control solution for oxy-fuel.

Slagger

The Slagger® cutting table is like no other in its ability to move slag. Whether produced from oxyfuel or plasma cutting, slag moves from one side of the table and deposits the slag into a collection bucket at the end of the table in just minutes.

Down Draft Table

The downdraft cutting table is like no other cutting table anywhere. The downdraft is specially designed to work with smaller machines and has a maximum plate capacity of 3" thick plate.

Camfill APC

Camfil APC is one of the top dust collector manufacturers worldwide with over 50 years of experience. Their dust collectors are specially engineered and designed with cutting machines in mind.

Donaldson

Donaldson provides filtration systems and replacement parts. Since 1915, Donaldson has developed its innovative technology, built strong customer relationships, and developed a broad geographic presence. Today they offer some of the highest quality dust collectors on the market.

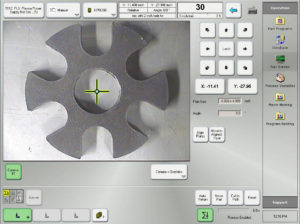

Global Control Plus

Easy-to-use, feature rich, Windows® interface. The Global Control Plus has a 24” touch screen with multiple process databases. A few of the key features include custom shape library, true shape nesting and productivity monitoring. Remote diagnostics and applications support is available with a push of a button.

OmniWin

MesserSoft OmniWin software is a simple, clear and fast designing and nesting software developed by MesserSoft. This software specially created for Messer machines, adapts intelligently, taking over cutting tasks for order-based production with additional CNC thermal cutting machines.

OmniBevel

OmniBevel is the professional software product for bevel cutting. It represents straight cuts, cylindrical holes, exact bevel angles and parts with absolute dimensional accuracy.

Customer Service

With 360° Messer Service we offer you five-star service programs ensuring your machine productivity and longevity. An important part of your business success is …

Maintenance

Purchase Preventative Maintenance and receive 30% savings on labor rates from a certified Messer technician. Plus 10% off on all related parts purchases; Plus 50% …

Virtual Service

Messer Cutting System offers the Virtual Service™ program in support of our complete line of cutting machines. This unique package allows our team of experts …

Training

In times of increasing competitive pressure, it is only logical to invest in the expertise and competence of your employees. After all, not only should …

Application

We see ourselves as customer oriented and innovative consultants. We to want help you open up new horizons of productivity to exceed your current demands …

Spare Parts & Consumables

Ensure optimum productivity for your systems by using original spare parts and consumables. We have current spare parts and consumables available for you with fast …

Optional Machine Features

Because every Messer machine is customized to fit our customers’ needs, the Titan III can be equipped with a range of options to promote optimal performance and efficiency.

- Up to 12 torch stations (maximum two plasma stations).

- Right or left hand mounted control console with tilt and swivel for operator comfort.

- Automatic torch spacing (with programmable torch selection).

- Programming and nesting software solutions for digitalization.

- Dust collection system.

- Sentry Service preventative maintenance program.

Process Tool Options

The Titan III plasma cutter can be modified to accommodate different applications and functions depending on your needs. Cutting options include:

- Precision Plasma (up to 800 amps).

- Advanced Oxyfuel technology (with an Omniflow automated gas regulation system).

- High-speed automated Oxyfuel cutting Turbo Flame™ or ALFA™ Oxyfuel torches.

- Electric drilling up to ½” diameter.

- Various plate markers, including: Plasma, Ink-jet, Air Scribe, Zinc Powder, and Telesis® Pinstamp.

Beveling Options

Precision and accuracy are critical elements of beveling. We can equip your Titan series plasma machine with the following bevel options for weld prep surfaces beveling (with options for straight line and contour, oxyfuel and plasma, single torch and multi-torch beveling):

Get Powerful Productivity With Messer’s Titan III

The Titan III combines Y-Axis linear ways with SureTrack pitch line rack and pinion drives to provide the smoothest cut edge and precise holes. Wider-end trucks with maximum guide roller spread further stabilizes the X-Axis motion for the utmost cut edge performance.