WHAT IS A DOWNDRAFT BURN TABLE?

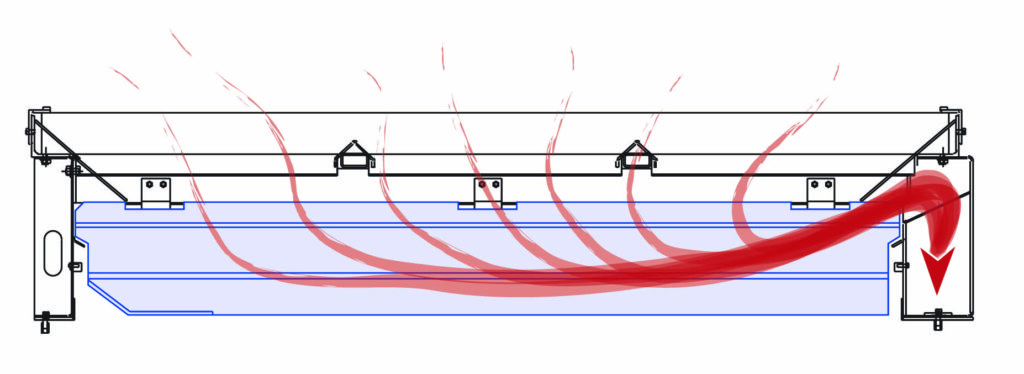

Downdraft burn tables are zoned and ducted, where smoke and dust particles are pulled down and extracted through the burn table into a dust collector. All downdraft tables require a dust collector. The Slagger® also includes a zoned downdraft table with mechanically operated damper doors actuated by a cam on the end truck of the machine. The damper doors automatically open as the machine passes over the zone where cutting is occurring.

The downdraft cutting table is like no other cutting table anywhere. Downdraft table is specially designed to work with smaller machines using plasma systems up to 400 amp and material up to 3″ (76.2 mm).

Downdraft burn tables are offered for gantry-style cutting machines. Messer Cutting Systems recommends The Slagger® and Shuttle Table.

- Table width 7′-4″ up to 24′ – 4″.

- Table length 10′-8″ up to 200′-0″.

- Small parts can be retrieved easily.

- The dust collector keeps the operating environment clean.

- The table does not have to be disassembled to remove the slag.

- Material Type: mild steel, stainless steel, and aluminum.

- Machine Model Compatibility: MetalMaster Evolution and other machines with 400 amp plasma or lower.

- Material Thickness Capacity: 26 gauge to 3″ (76.2mm).

Contact

Messer Cutting Systems, Inc.

What is the plate capacity for a downdraft burn table?

The maximum workpiece thickness for the standard downdraft burn table varies with table width. Standard table sizes are available to meet the specific requirements of the cutting machine. Reinforced tables to accommodate for thicker material are available.

How does a downdraft table work?

This table is able to automatically move the small parts and slag produced from either oxy-fuel or plasma cutting from the table bottom to the end of the table. A pusher type blade moves the small parts and slag forward into the optional pan located at the front of the plasma cutting table.

The Slagger® is also an excellent smoke removal table. Smoke is drawn from the table by a side duct that is divided into zones. The zones open only at the plasma cutting machine location.

Downdraft burn tables are available on:

- Messer Cutting Systems’ PlateMaster II, designed as plasma and oxyfuel cutting machine including marking. The PlateMaster II cutting machine has machine cutting widths of 6, 8, 10, and 12 feet and lengths up to 72 feet. The burn table is separate from the cutting machine.

- The Titan III is designed as a plasma and oxyfuel cutting machine, including drilling and marking. The Titan III cutting machine has machine cutting widths of 6’ to 16’ and lengths up to 150’. The burn table is separate from the cutting machine.

- Messer Cutting Systems’ MPC2000, is designed as a plasma and oxyfuel cutting machine, including drilling and marking. The MPC2000 cutting machine has machine cutting widths of 8 to 28 feet and lengths up to 200 feet. The burn table is separate from the cutting machine.

- Our MPC2000 MC, built for plasma and oxyfuel cutting, including drilling, milling, and marking. The MPC2000 MC cutting machine has machine cutting widths of 12 to 28 feet and lengths extending up to 200 feet. The burn table is separate from the cutting machine.

- The TMC4500 DB, designed for plasma and oxyfuel cutting, including drilling, milling, and marking. The TMC4500 DB cutting machine has machine cutting widths of 12 to 28 feet and lengths up to 200 feet. The burn table is separate from the cutting machine.

- Our SicoMAT®, engineered for oxyfuel cutting, including drilling, marking, milling, and grinding. The SicoMat® cutting machine has machine cutting widths of 12 to 68 feet and lengths up to 200 feet. The burn tables are separate from the cutting machine.