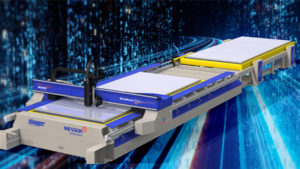

The SicoMat® offers high productivity and maximum robustness: characteristics which are required particularly in shipbuilding and wind tower manufacture. With bevel cutting heads for oxyfuel and plasma, a wide spectrum of marking processes, and the possibility of having a sandblasting or grinding head, the Sicomat® covers all production requirements.

- For oxyfuel cutting.

- High level of automation.

- Simple operation.

- High productivity.

- AS drives with a speed of up to 24 m/min.

- Torsion resistant double beam bridge.

- Highest stability even with heavy tools.

- Maximum robustness.

Contact

Messer Cutting Systems, Inc.

COMPONENTS

Oxyfuel Bevel Cutting

Messer Cutting Systems offers a variety of bevel cutting units, perfectly suited for your cutting applications. You can choose oxy-fuel options, in both automatic and …

DAF/L

The automatic infinitely rotating triple bevel head D/AFL is created for V, X, Y and K cuts.

Oxyfuel Contour Bevel Unit

The Oxy-fuel Contour Bevel Unit provides continuous bevel cuts in mild steel with automatic contour control, manual ignition and bevel angle adjustment.

Three Position Oxyfuel Bevel Unit

Manually adjusted Triple Torch Oxyfuel Bevel Unit for straight line bevels with manual gas adjustment and manual ignition.

Single Position Oxyfuel Bevel Unit

Manually adjusted Single Position Triple Torch Oxy-fuel Bevel Unit for straight line bevels with manual ignition and gas adjustment.

ALFA Oxyfuel Torch

The Messer Cutting Systems developed ALFA oxy-fuel torch takes oxy-fuel cutting to an entirely new level. The ALFA torch internalizes many features that used to have to be on the outside of an oxy-fuel torch, including height sensing and auto-ignition.

Turbo Flame Torch

Our Turbo Flame™ Torch is very versatile, able to be used with a variety of fuel gases and is very safe to operate.

OmniFlow

The Omniflow Automatic Gas Control System delivers automatic setting and regulation of preheat oxygen, cutting oxygen and fuel gas pressure during oxyfuel cutting.

Dual Hi-Lo

Dual Hi-Lo Manual Gas Control System is an economical gas control solution for oxy-fuel.

FT-100 Torch Igniter

Messer Cutting Systems FT100 Torch Ignitor remotely ignites any brand of oxyfuel torch. Since no arc is struck, critical alignment is not needed allowing for easy and fast tip change out.

SL200 & SL300 Oxyfuel Lifters

The SL200 PLASMA AND OXYFUEL SMARTLIFTERS include several productivity enhancing features to produce more parts in a shorter period of time. An adaptive initial height sense system “learns” the height of the plate on the cutting table to quickly position the torch to the correct pierce height.

SensoMat-PAN

SensoMat®-PAN Height Sensing for oxyfuel reliably maintains the proper standoff distance between the oxyfuel torch tip and the work piece, without operator intervention.

Ink-jet Marker

Ink-jet marking delivers fast and quiet alphanumeric labeling with printing in one direction of travel for non-rotational unit or multi-directional with rotating unit.

Telesis PinStamp Marker

The Telesis® Pinstamp® marking system uses a reciprocating stylus permanently prints messages on to a variety of plate such as mild steel, stainless steel, and aluminum.

Digital Video Camera

Monitor the cutting process with Messer Cutting Systems’ Digital Video Camera. This product assists in remote diagnostics using Virtual Service™ and gives your team the benefit of having a bird’s-eye view of the cutting process.

Laser Pointer

Our Laser Pointer enables the operator to identify the edge or other feature of the plate physically with a known location on the cutting machine, simplifying the basic setting, shortening throughput times and avoiding scrap.

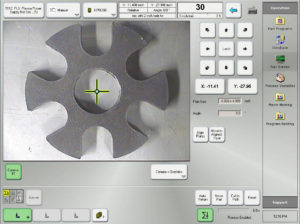

Control

Easy-to-use, feature rich, Windows® interface. The Global Control Plus has a 24” touch screen with multiple process databases. A few of the key features include custom shape library, true shape nesting and productivity monitoring. Remote diagnostics and applications support is available with a push of a button.

Slagger

The Slagger® cutting table is like no other in its ability to move slag. Whether produced from oxyfuel or plasma cutting, slag moves from one side of the table and deposits the slag into a collection bucket at the end of the table in just minutes.

Donaldson Torit

Donaldson provides filtration systems and replacement parts. Since 1915, Donaldson has developed its innovative technology, built strong customer relationships, and developed a broad geographic presence. Today they offer some of the highest quality dust collectors on the market.

Camfil Farr

Camfil APC is one of the top dust collector manufacturers worldwide with over 50 years of experience. Their dust collectors are specially engineered and designed with cutting machines in mind.

OmniWin

MesserSoft OmniWin software is a simple, clear and fast designing and nesting software developed by MesserSoft. This software specially created for Messer machines, adapts intelligently, taking over cutting tasks for order-based production with additional CNC thermal cutting machines.

Maintenance

With 360° Messer Service we offer you five-star service programs ensuring your machine productivity and longevity. An important part of your business success is …

Training

We guarantee you a fast, consistent and high quality support for our software solutions. Our technical hotline offers you individual service for specific technical questions …

Applications

We see ourselves as customer oriented and innovative consultants. We to want help you open up new horizons of productivity to exceed your current demands …

Spare Parts & Consumables

Ensure optimum productivity for your systems by using original spare parts and consumables. We have current spare parts and consumables available for you with fast …

The rigid, double beam bridge design offers stability even with the heaviest tools, and the high accuracy is well known for remaining over many years, even in rough environments.

A high level of automation (even the weld edge geometry can be programmed and set automatically) ensures productivity and ease of operation.

Have you any questions about our cutting machines or would you like more information about any aspect of our product range? As suppliers of solutions to problems for the metalworking industry it is extremely important to us that we always offer you the best solution for your individual requirements. Contact us and we

will reply to you as fast as possible.