MetalMaster Evolution®

Revolutionizing Plate Processing

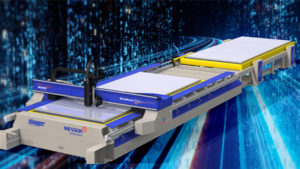

Evolving to meet the needs of the modern fabrication shop, solving costly secondary operations downstream, the unitized plasma cutting machine MetalMaster Evolution® will change the way you look at plasma part cutting.

This high-speed, multiple-process plasma cutting machine is built to deliver maximum productivity and durability as well as outstanding cut quality and accuracy. Messer Cutting Systems’ MetalMaster Evolution® comes outfitted with a number of standard features like The Slagger® cutting table and includes scores of optional features such as plasma beveling, oxyfuel cutting, drilling, marking, vertical pipe cutting, water table, and so much more.

MetalMaster Evolution® Highlights

The MetalMaster Evolution® is a feature-rich plasma cutting machine, offering smooth edge quality, precise hole cutting, and high accuracy.

With high-quality components and the strictest assembly and testing methods within the marketplace, the MetalMaster Evolution® will take your shop to the next level.

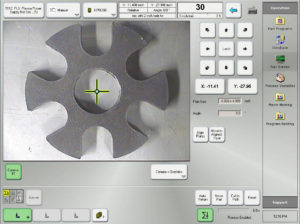

Global Control

The MetalMaster Evolution® has an easy-to-use Windows® 10 interface. The Global ControlS is a compact touch-screen process database featuring a custom shape library, CAD import, and True-Shape Nesting. Service experts are just a button push away via Virtual Service™. Easy-to-learn functions enable employees to become expert operators in minutes.

Axis Drives

The MetalMaster Evolution® features high machine accuracy with positioning speeds up to 1,700 inches per minute with an acceleration of 38 inches per second2 in all axes. This plasma-cutting machine also features precision rack-and-pinion drives in the X and Y axes. It also has ultra-smooth planetary gearboxes in the X and Y axes. Dual X-axis drives provide accuracy in cut parts.

Bearings Assembly

Each MetalMaster Evolution® carriage uses four-bearing way encapsulation with wide spacing to provide stable support. Gothic arch bearings on circular ways provide eight contact points per carriage for smooth precise motion. Ways and gear racks are attached to the way surfaces by special grooves in the extrusion, enabling future table extensions.

Beam Support

The MetalMaster Evolution® also features an extruded aluminum beam and X-axis ways, providing support and high strength while reducing weight. The cross-braced beam is extremely rigid, providing higher acceleration and resulting in accurate cut parts and smooth motion.

Contact

Messer Cutting Systems, Inc.

Downloads

THE SLAGGER® SELF-CLEANING UNITIZED TABLE COMES WITH THE METALMASTER EVOLUTION®

The Messer Slagger® self-cleaning unitized side-draft zoned and ducted table comes standard on the MetalMaster Evolution, forming a solid foundation for this table.

There’s no need to clean the table or remove slats as the pusher blade does all the work, usually in mere minutes.

The Slagger® allows for easy small parts retrieval. An optional water table is also available.

MetalMaster Evolution® Specifications

Messer Cutting Systems’ MetalMaster Evolution® comes with many standard features as well as optional features to help your business get more out of your plasma cutting machine.

MetalMaster Evolution® Standard Features

- Machine cutting widths available are 6 feet (1.8 meters), 8 feet (2.4 meters), and 10 feet (3 meters).

- Cutting lengths: 10 foot (3 meters) machines can expand in 5 foot (1.524 meters) increments to 50 feet (15.24 meters).

- Cut 26-gauge to 3 inch-thick plate.

- Cuts mild steel, stainless steel, and aluminum.

- Machine motion accuracy is an exceptional +/- 0.002 inches (0.45 millimeters) over any 6-foot x 10 foot (1.8-meter x 3-meter) area and verified with a laser interferometer.

- Positioning speeds up to 1,700 inches per minute with acceleration up to 38 in./sec2.

- Contouring speeds up to 400 inches per minute.

- The Slagger® self-cleaning zoned and ducted dry exhaust table.

- Windows® based Global ControlS with easy-to-use operator interface.

- Uses an aluminum beam extrusion for extra stability and support.

- Right or left-hand mounted Global Control tilts and swivels for operator comfort.

- Multiple reference point positions for efficient start-of-cut locations.

- SureStop Collision Sensor with easy and accurate reset.

- Advanced plasma technology provides consistent piercing and faster cutting.

- High-speed CSL200 Torch lifter.

- Fast installation and relocation due to modular design.

- Virtual Service™ remote diagnostics and consultation.

- Designed and manufactured in the USA to machine tool and ISO 230-2 standards.

- UL/CUL-certified.

MetalMaster Evolution® Optional Features

- Two plasma torches, each with a maximum of 400 amp capacity.

- Plasma beveling units: Bevel-R® 5-Axis, Compact Plasma Bevel Unit with SureStop Collision Sensor, Manual Plasma Stripping Bevel Unit for X-Axis.

- Turbo Flame™ or ALFA Oxyfuel Torch.

- Gas cutting with advanced oxyfuel technology using the Omniflow automated gas regulation system.

- FT100 Torch Ignitor.

- SensoMat® PAN.

- Various plate markers: Plasma, Air Scribe, Ink-Jet, and Telesis® Pinstamp®.

- Digital video camera.

- Laser pointer.

- Global Reporter.

- Two-zoned protection systems.

- Enclosure.

- Slag Scoop or Slag Bucket with Pit.

- Manual cleaning or water table.

- Plasma station outlet equipment.

- Plasma Air Booster.

- Programming and nesting software.

- Drilling up to a ⅜-inch diameter.

- Operator Swing-Away Glare Curtain or Glare Shield at the torch.

- Flex Zone for processing material outside the table.

- Vertical pipe and tube cutting.

- Pedestal-mounted console.

- Messer dust collector systems.

- Sentry Service Preventative Maintenance Program.

- Visual Service adds a sense of sight to the troubleshooting process.

COMPONENTS

Messer offers a variety of process tools. All Messer machines are completely customized. The benefits of a customized cutting machine fit for your company’s needs can make you the leader of productivity in your industry. When you need a machine that outperforms all others and provides you with the capability of bevel cutting, drilling, tapping, and marking, all on a variety of materials from thin plate to thick steel with an excellent cut part quality, then Messer Cutting Systems is your machine of choice.

Straight Line Plasma Cutting

Our products cover the whole range of cutting tasks in modern metal industries. Using different thermal cutting technologies for straight plasma cutting, our machines can be easily adapted to your shop’s requirements.

Bevel-R™

This compact 5-Axis plasma bevel cutting unit with collision protection has been conceived as an entry device for occasional bevel cutting.

Manual Plasma Stripping Bevel Unit for the X-Axis

Messer Cutting Systems’ Manual Plasma Bevel Unit provides an adapter mounting between the SureStop breakaway and the lifter. This component enables straight-line motion bevel cutting in the X-axis.

ALFA

The Messer Cutting Systems developed ALFA oxy-fuel torch takes oxy-fuel cutting to an entirely new level. The ALFA torch internalizes many features that used to have to be on the outside of an oxy-fuel torch, including height sensing and auto-ignition.

TurboFlame

Our Turbo Flame™ Torch is very versatile, able to be used with a variety of fuel gases and is very safe to operate.

Omniflow Automatic Gas Control System

The Omniflow Automatic Gas Control System delivers automatic setting and regulation of preheat oxygen, cutting oxygen and fuel gas pressure during oxyfuel cutting.

FT-100 Torch Ignitor

3/8" Drilling

An optional drill feature can be combined with a normal plasma and oxyfuel cutting, allowing for form work to be done on the piece part in a single handling.

Air Scribe

Ink-Jet

Ink-jet marking delivers fast and quiet alphanumeric labeling with printing in one direction of travel for non-rotational unit or multi-directional with rotating unit.

Plasma Marking

Plasma marking is suitable for the engraving of lines, contours and characters on plate surfaces.

Telesis Pinstamp

Digital Video Camera

Monitor the cutting process with Messer Cutting Systems’ Digital Video Camera. This product assists in remote diagnostics using Virtual Service™ and gives your team the benefit of having a bird’s-eye view of the cutting process.

Vertical Pipe and Tube Cutting

Messer Cutting Systems Pipe and Tube Cutting System for all Messer machines. Offline software provided by Lantek specialist in 3D pipe and tube profiling, is used to easily create CNC programs for the Messer Global Control for both vertical and bevel cutting, available in multiple machine sizes. Steel pipe and tube cutting machines are built in the USA.

Slagger

Camfill APC

Camfil APC is one of the top dust collector manufacturers worldwide with over 50 years of experience. Their dust collectors are specially engineered and designed with cutting machines in mind.

Donaldson

Donaldson provides filtration systems and replacement parts. Since 1915, Donaldson has developed its innovative technology, built strong customer relationships, and developed a broad geographic presence. Today they offer some of the highest quality dust collectors on the market.

OmniWin

MesserSoft OmniWin software is a simple, clear and fast designing and nesting software developed by MesserSoft. This software specially created for Messer machines, adapts intelligently, taking over cutting tasks for order-based production with additional CNC thermal cutting machines.

OmniFab

OmniFab is the IoT software suite that offers you cutting technology as a tailor-made solution for your order-related production. It integrates Messer mechanical engineering technology into your daily business processes.

Customer Service

With 360° Messer Service we offer you five-star service programs ensuring your machine productivity and longevity. An important part of your business success is …

Maintenance

Purchase Preventative Maintenance and receive 30% savings on labor rates from a certified Messer technician. Plus 10% off on all related parts purchases; Plus 50% …

Virtual Service

Messer Cutting System offers the Virtual Service™ program in support of our complete line of cutting machines. This unique package allows our team of experts …

Spare Parts & Consumables

Ensure optimum productivity for your systems by using original spare parts and consumables. We have current spare parts and consumables available for you with fast …

Training

In times of increasing competitive pressure, it is only logical to invest in the expertise and competence of your employees. After all, not only should …

Application

We see ourselves as customer oriented and innovative consultants. We to want help you open up new horizons of productivity to exceed your current demands …

LEARN MORE

Achieve smooth edge quality, precise hole cutting and high accuracies through advanced engineering. With its high-quality components and the strictest assembly and testing methods in the marketplace, the Messer Cutting Systems plasma cutting machine MetalMaster Evolution® will take your shop to the next level.

Beyond its capable standard features, this multiple-process cutting machine can be made more robust with our many valuable optional features, from plasma beveling and oxyfuel cutting to drilling, marking and vertical pipe cutting.